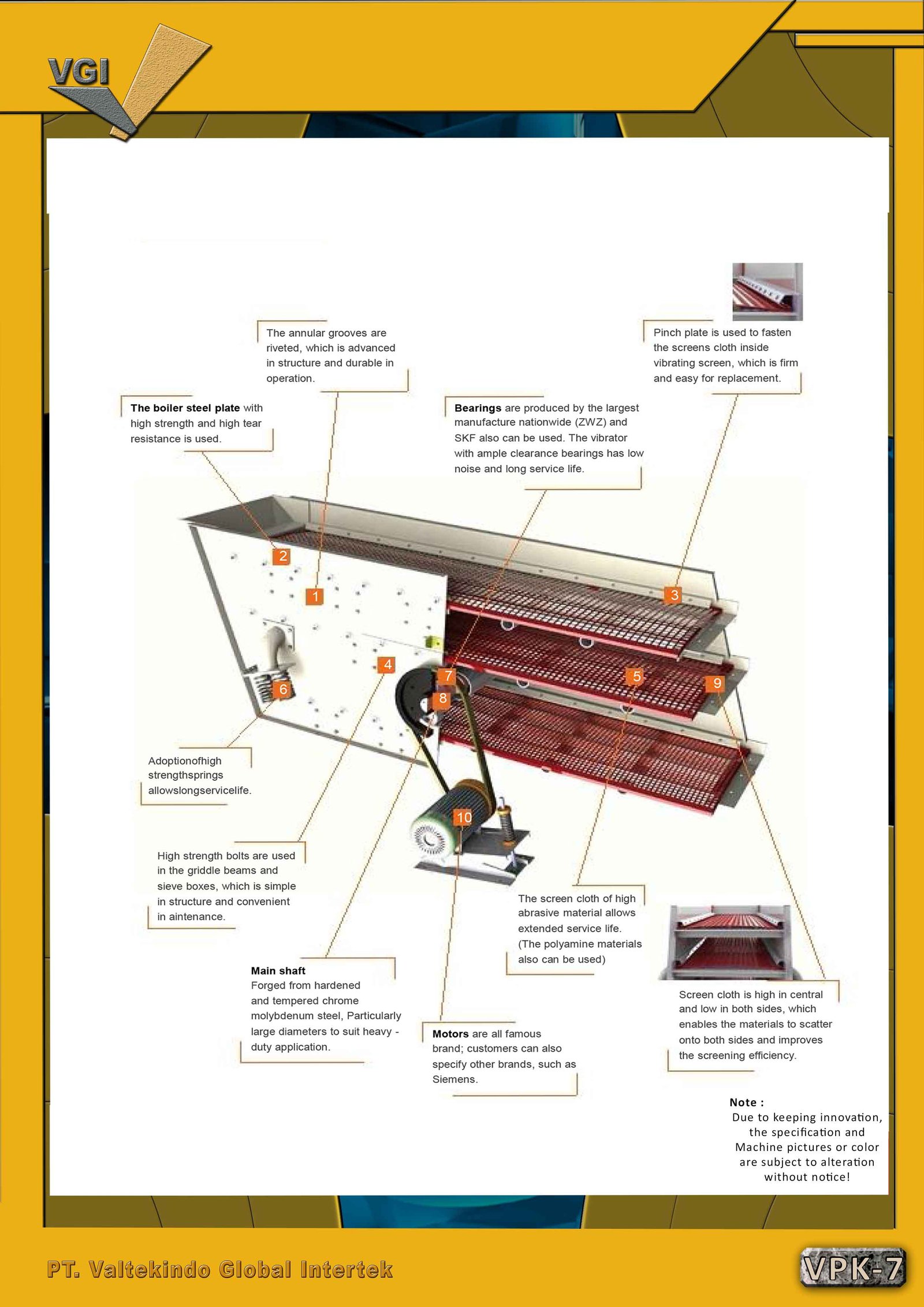

Vibrating Screen 2

1. The annular grooves are riveted, which is advanced in structure and durable in operation.

2. The boiler steel plate with high strength and high tear resistance is used.

3. Pinch plate is used to fasten the screens cloth inside vibrating screen, which is firm and easy for replacement.

4. High strength bolts are used in the griddle beams and sieve boxes, which is simple in structure and convenient in maintenance

5. The screen cloth of high abrasive material allows extended service life. (the polyamine materials also can be used)

6. Adoption of high strength springs allows long service life

7. Bearing are produced by the largest manufacture nationwide (ZWZ) and SKF also can be used. The vibrator with ample clearance bearings has low noise and long service life.

8. Main shaft forged from hardened and tempered chrome molybdenum steel, particularly large diameters to suit heavy – duty application

9. Screen cloth is high in central and low in both sides, which enables the materials to scatter on to both sides and improves the screening efficiency.

10. Motors are all famous brand; customers can also specify other brands, such as Siemens.