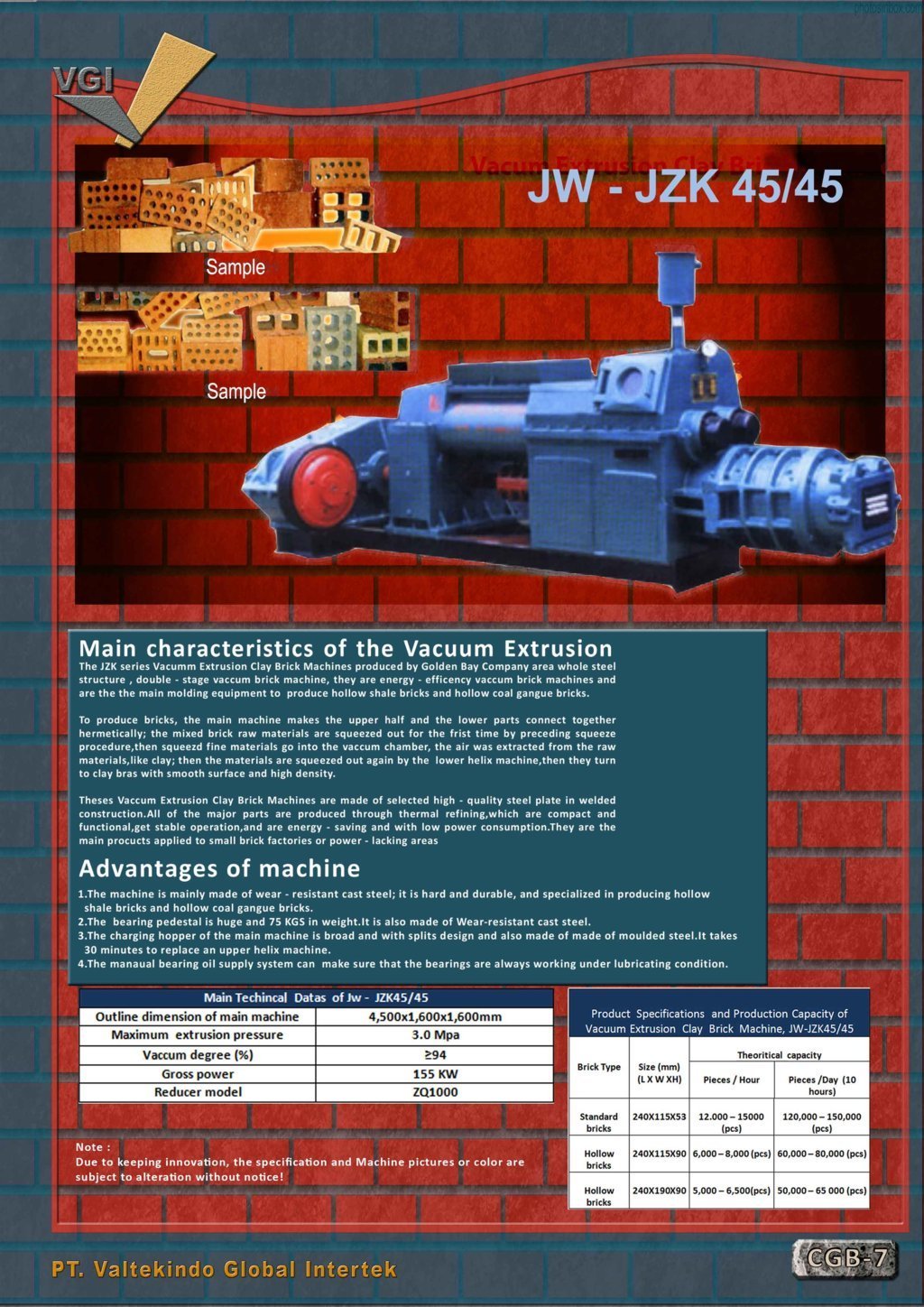

Vacuum Extrusion

JW

– JK 45/45

Main

characteristic of the Vacuum Extrusion

The JZK series

Vacuum Extrusion Clay Brick Machines produced by Golden Bay Company area whole

steel structure, double – stage vacuum brick machine, they are energy –

efficiency vacuum brick machines and are the the main molding equipment to

produce hollow coal gangue brcks.

To produce bricks,

the main machine makes the upper half and the lower parts connect together

hermetically; the mixed brick raw

materials are squeezed out for the first time by preceding squeeze procedure,

then squeeze fine materials go into the vacuum chamber, the air was extracted

from the raw materials, like clay; then the materials are squeezed out again by

the lower helix machine, then they turn to clay bras with smooth surface and

high density.

Theses vacuum

Extrusion Clay Brick Machines are made

of selected high-quality steel plate in welded construction. All of the major

parts are produced through thermal refining, which are compact and functional.

Get stable operation, and energy – saving and with low power consumption. They are

the main products applied to small brick factories or power – lacking areas.

Advantages

of machine

1.

The

machine is mainly made of wear – resistant cast steel; it is hard and durable,

and specialized in producing hollow shale bricks and hollow coal gangue bricks.

2. The bearing pedestal is huge and

75 KGS in weight. It is also made of wear – resistant cast steel.

3. The charging hopper of the main

machine is board and with splits design and also made of made of moulded steel.

It takes 30 minutes to replace an upper helix machine.

4.

The

manual bearing oil supply system can make sure that the bearings are always

working under lubricating condition.

|

Main

Technical Data of Jw – JZK45/45 |

|

|

Outline

dimension of main machine |

4.500x1,600x1,600mm |

|

Maximum

extrusion pressure |

3.0

Mpa |

|

Vacuum

degree (%) |

≥94 |

|

Gross

power |

155

kW |

|

Reducer

model |

ZQ1000 |

|

Product

Specification and Production Capacity of Vacuum Extrusion Clay Brick Machine,

JW-JZK45/45 |

|||

|

Brick

Type |

Size

(mm) (L

X W X H) |

Theoretical

capacity |

|

|

Pleces

/ Hour |

Pleces

/ Day (10 hours) |

||

|

Standard

bricks |

240X115X53) |

12.000

– 15000 (pcs) |

120.000

– 150.000 (pcs) |

|

Hollow

bricks |

240X115X90 |

6.000

– 8.000 (pcs) |

60.000

– 80.000 (pcs) |

|

Hollow

bricks |

240X190X90 |

5.000

– 6.500 (pcs) |

50.000

– 65.000 (pcs) |