Transparent Electro Hydraulic Trainer

Equipment

Overview

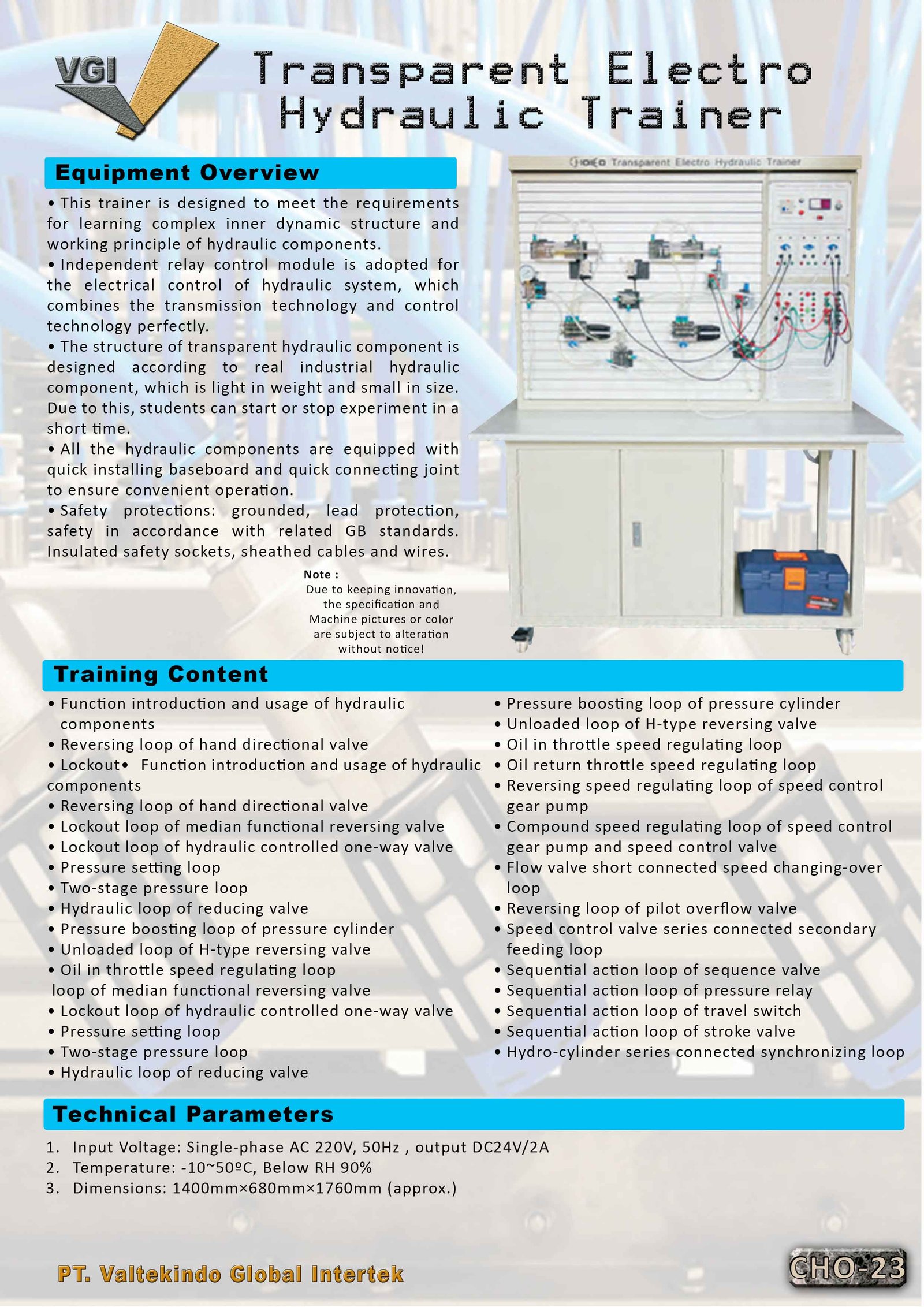

· this trainer is designed to meet the requirements for learning complex inner dynamic structure and working principle of hydraulic components .

· independent relay control module is adopted for the electrical control of hydraulic system , swich combines the transmission technology and control technology perfectly .

· the structure of transparent hydraulic components is designed according to real industrial hydraulic components , which is light and small in size . due to this , students can star or stopexperiment in a short time .

· all the hydraulic components are equipped with quick installing baseboard and quick connecting joint to ensure convenient operation .

· safety protections : grounded, lead perotection , safety in accordance with related cables and wires .

Training Content

· function introduction and usage of hydraulic components

· reversing loop of hand directional valve

· lockout . function introduction and usage of hydraulic components

· reversing loop of hand directional valve

· lockout loop of median directional valve

· lockout loop of hydraulic controlled one – way valve

· pressure setting loop

· two-stage pressur loop

· hydraulic loop of reducing valve

· pressure boosting loop of pressure clinder

· unloaded loop of H-type reversing valve

· oil in throttle speed regulating loop

loop of median fuctional reversing valve

· lockout loop of hydraulic controlled one – way valve

· pressure setting loop

· two-stage pressure loop

· hydraulic loop of reducing valve

· pressure boosting loop of preesure cylinder

· unloaded loop of H-type reversing valve

· oil in throttle speed regulating loop

· oil return throttle speed regulating loop

· reversing speed regulating loop of speed control gear pump

· compound speed regulating loop of speed control gear pump and speed control valve

· flow valve shorts connected speed changing-over loop

· reversing loop of pilot overflow valve

· speed control valve series connected secondry feeding loop

· sequential action loop of sequence realay

· sequential action loop of pressure relay

· sequential action loop of travel switch

· sequential action loop of stroke valve

· hydro-clinder series connected synchronizing loop.

Technical Parameters

1. input voltage : single – phese AC 220V , 50Hz output DC24V/2A

2. Temperature : 10 ~50°C , below RH 90 %

3. dimensions: 1400mmx680mmx1760mm (approx)