Top Loading Washing Machine Maintenance and Assessment Trainer 1

Top Loading Washing Machine Maintenance

Equipment Overview

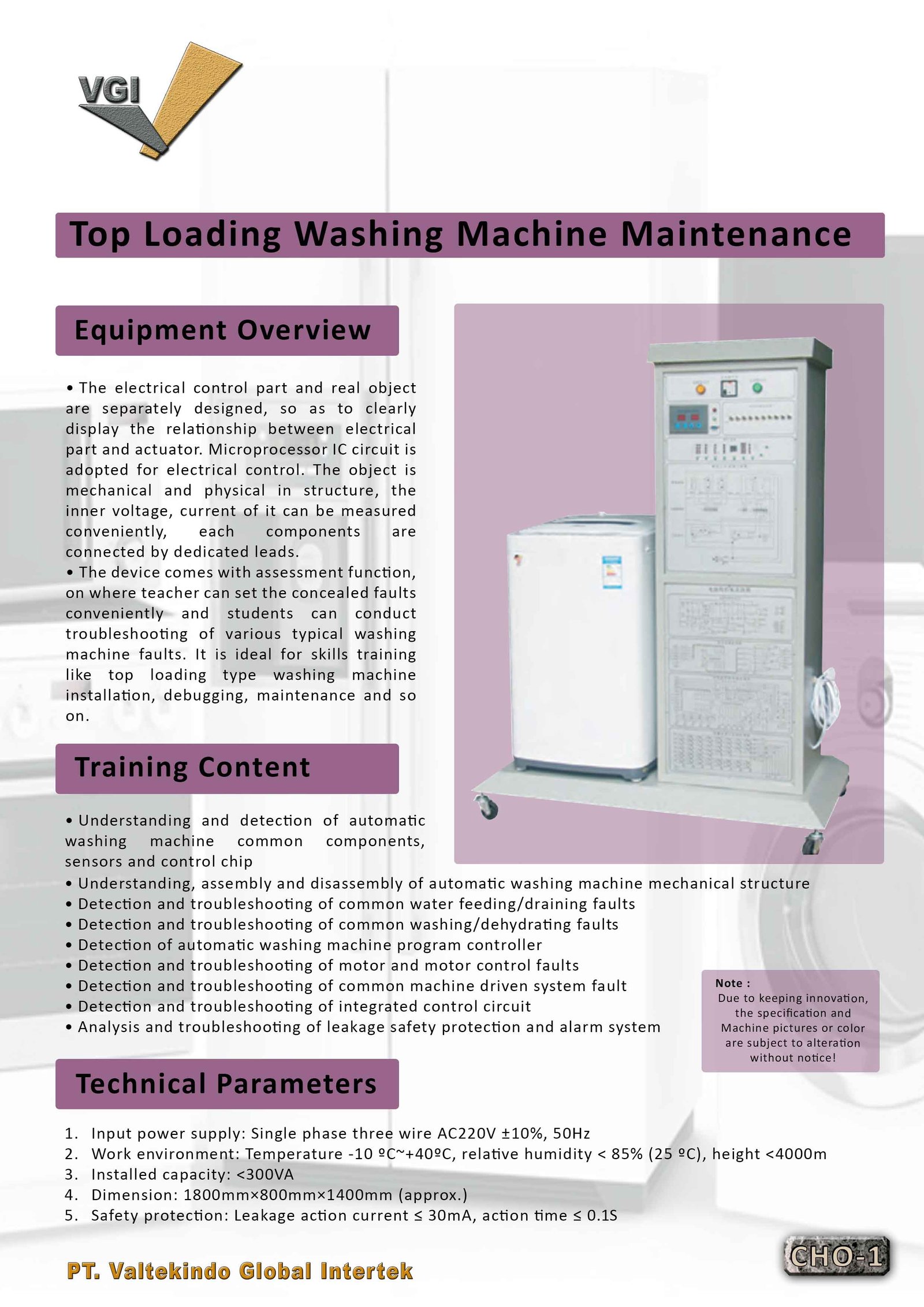

· The electrical control part and real object are separately designed, so as to clearly display the relationship between electrical part and actuator. Microprocessor IC circuit is adopted for electrical control. The object is mechanical and physical in structure, the inner voltage, current of it can be measured conveniently, each components are connected by dedicated leads.

· The device comes with assessment function, on where teacher can set the concealed faults conveniently and students can conduct troubleshooting of various typical washing machine faults. It is ideal for skills training like top loading type washing machine installation, debugging, maintenance and so on.

Training Content

· Understanding and detection of automatic washing machine common components, sensors and control chip.

· Understanding, assembly and disassembly of automatic washing machine mechanical structure

· Detection and troubleshooting of common water feeding/draining faults

· Detection and troubleshooting of common washing/dehydrating faults

· Detection of automatic washing machine program controller

· Detection and troubleshooting of motor and motor control faults

· Detection and troubleshooting of common machine driven system fault

· Detection and troubleshooting of integrated control circuit

· Analysis and troubleshooting of leakage safety protection and alarm system

Technical Parameters

1. Input power supply: Single phase three wire AC220V ±10%, 50Hz

2. Work environment: Temperature -10 ºC~+40 ºC, relative humidity < 85% (25 ºC), height <4000m

3. Installed capacity: <300VA

4. Dimension: 1800mmx800mmx1400mm (approx)

5. Safety protection: Leakage action current ≤ 30mA, action time ≤ 0.15