Three-laye Co-extruding Plastic Sheet Machine

Structure

characteristic :

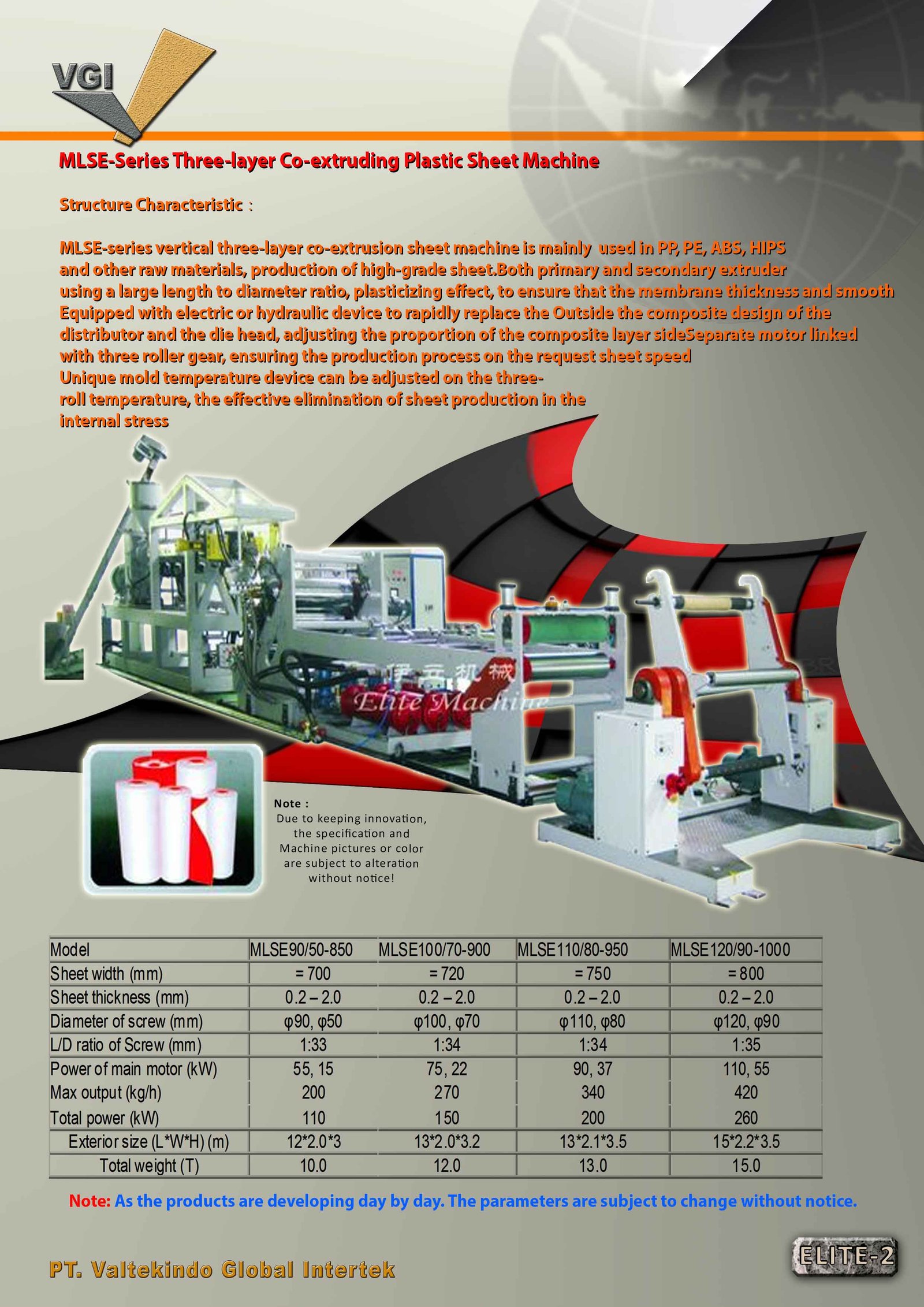

MLES-series verticals three-layer sheet machine is mainly used in PP,PE,ABS,HIPS and other raw materials, production of high-grade sheet, both primary and secondary extruder using a large length to diameter ratio, plasticizing effect, to ensure that the membrane thickness and smooth equipped with electric or hydraulic device to rapidly replace the outside composite design of the distributor and the die head , adjusting the proportion of the composite layer side separate motor linked with three roller gear, ensuring the production process on the request sheet speed unique mold temperature device can be adjusted on the three- roll temperature, the effective elimination of sheet production in the internal stress

|

model |

MLES90/50-850 |

MLSE100/70-900 |

MLSE110/80-950 |

MLSE120/90-1000 |

|

Sheet

width(mm) |

=70 |

=720 |

=750 |

=800 |

|

Sheet

thickness(mm) |

0.2-2.0 |

0.2 2.0 |

0.2-2.0 |

0.2 2.0 |

|

Diameter

of screw(mm) |

ɸ90,ɸ50 |

ɸ100,ɸ70 |

ɸ110,ɸ80 |

ɸ120,ɸ90 |

|

L/D

ratio of screw(mm) |

1:33 |

1:34 |

1:34 |

1:35 |

|

Power of

main motor (kW) |

55,15 |

75,22 |

90,37 |

110,55 |

|

Max

output(kg/h) |

200 |

270 |

340 |

420 |

|

Total

power(Kw) |

110 |

150 |

200 |

260 |

|

Exterior

size(L*W*H)(m) |

12*2.0*3 |

13*2.0*3.2 |

13*2.1*3.5 |

15*2.2*3.5 |

|

Total

weight (t) |

10.0 |

12,0 |

13.0 |

15.0 |