Steel Plastic Composite Geogrid Production Line

PRODUCT INTRODUCTION

Steel plastic composite geogrid is a kind of composite high-tensile belt which processed high tensile steel wire

in a special way, with PE and some other additives, by extrusion and surface embossed. Steel plastic composite warp knitted geogrid is made of this belt by stretched in both lengthways and transverse way, with certain distance knitting or clamping arranged, it adopts special strengthen bonding fusion welding technique, with welding the

crossings to form. Steel plastic composite warp knitted geogrid ultrasonic welding forming machine is a weld host group formed by numbers of ultrasonic plastic welder single machine, which has absorbed the most advanced ultrasonic techno logy all over the world. With the important component of ultrasonic generator using import materials, energy converter using Germany piezoelectric ceramic plate, moulds using American import aluminium alloy. The overall unit has superior performance, with features such as low power consumption, long operating life, high welding precision and so on. It is widely used in railway and highway roadbed protection, dam, bridge abutment, ramp, shoals polder, tailings dam, slag yard, inner hargour dock, landslip repair and so on.

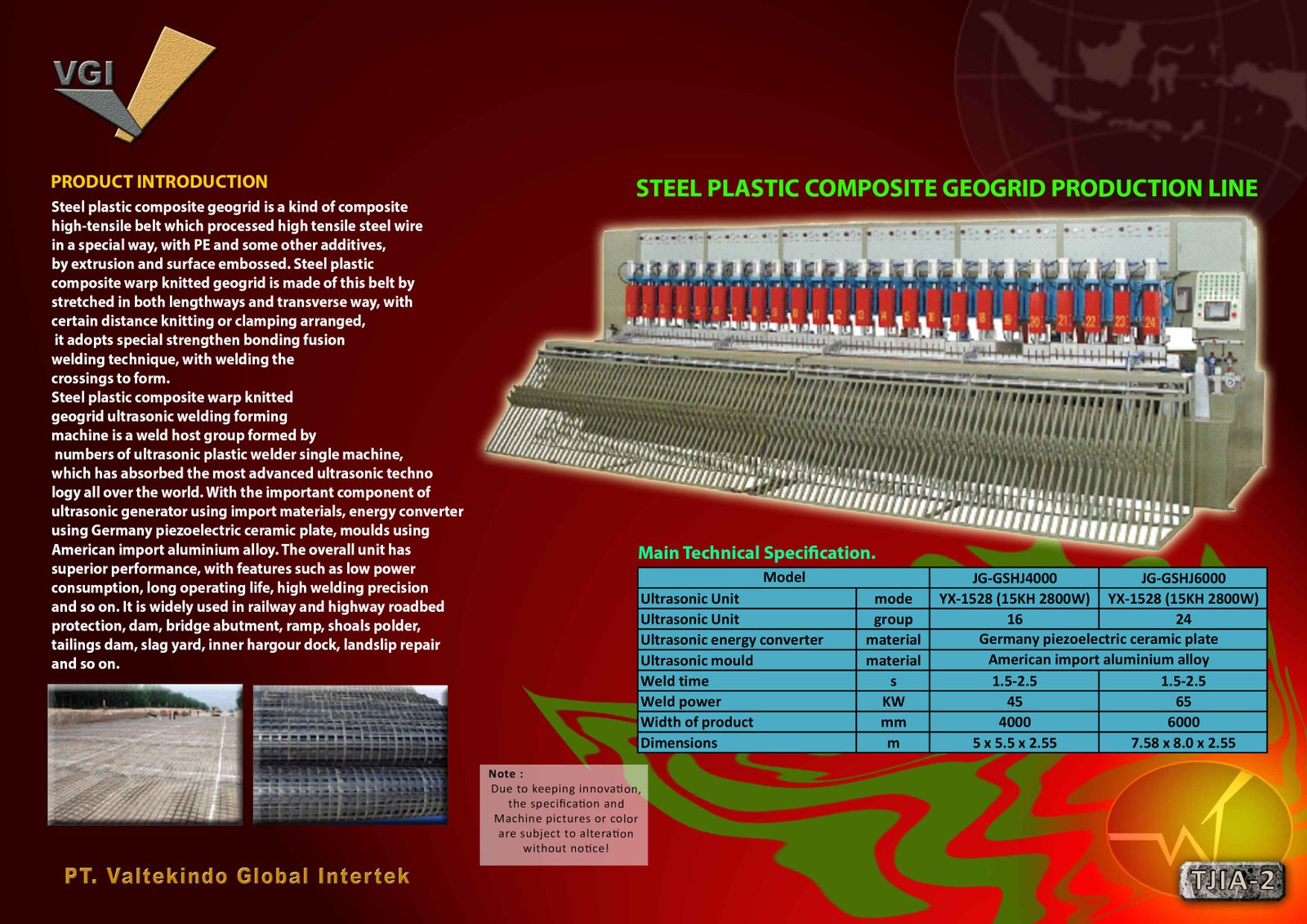

Main Technical

Specification

|

Model |

JG-GSHJ4000 |

JG-GSHJ6000 |

|

|

Ultrasonic Unit |

Mode |

YX-1528 (15KH 2800W) |

YX-1528 (15KH 2800W) |

|

Ultrasonic Unit |

Group |

16 |

24 |

|

Ultrasonic energy converter |

Material |

Germany piezoelectric ceramic plate |

|

|

Ultrasonic mould |

Material |

American import aluminum alloy |

|

|

Weld time |

S |

1.5-2.5 |

1.5-2.5 |

|

Weld Power |

KW |

45 |

65 |

|

Width product |

Mm |

4000 |

6000 |

|

Dimension |

m |

5 x 5.5 x 2.55 |

7.58 x 8.0x2.55 |