Steel Bar Bending Testing Machine Series

Usage and Characteristic

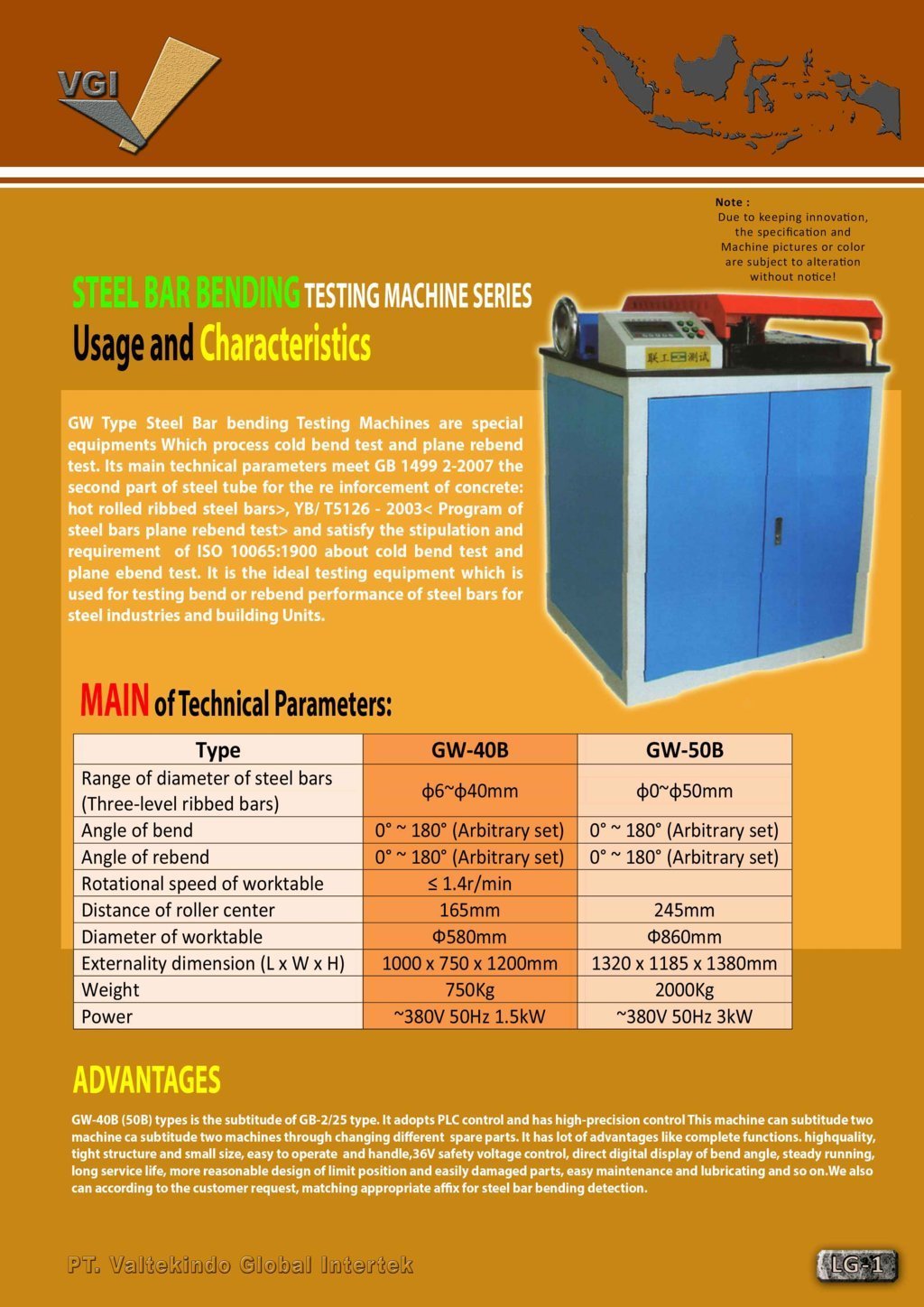

GW Type Steel Bar bending Testing Machines are special equipments Which process cold bend test and plane rebinds test. Its main technical parameters meet GB 1499 2-2007 the second part of steel tube for the re enforcement of concrete: hot rolled ribbed steel bars>, YB/T5126 – 2003 < Program of steel bars plane relend test > and satisfy the stipulation and requirement of ISO 10065:1900 about cold bend test and plane bend test. It is the ideal testing equipment which is used for testing bend or rebend performance of steel bars for steel industries and building units.

Advantages

GW-40B (50B) types is substitute of GB-2/25 type. It adopts PLC control and high-precision control this machine can substitute two machine can substitute two machines through changing different spare part. It has lot advantages like complete functions. High quality tight structure and small size, easy operate and handle, 36V safety voltage control, direct digital display of bend angle, steady running, long service life, more reasonable design of limit position and easily damaged parts, easy maintenance and lubricating and so on. We also can according to the customer request, matching appropriate affix for steel bar bending detection.

Main of Technical Parameters

|

Type |

GW-40B |

GW-50B |

|

Range of diameter of steel bars

(Three-level ribbed bars) |

ɸ6~

ɸ40mm |

ɸ0~ ɸ50mm |

|

Angle of bend |

0°180° (Arbitrary set) |

0°180° (Arbitrary set) |

|

Angle of rebend |

0°180° (Arbitrary set) |

0°180° (Arbitrary set) |

|

Rotational speed of worktable |

≤ 1.4r/min |

|

|

Distance of roller center |

165mm |

245mm |

|

Diameter of worktable |

ɸ580mm |

ɸ860mm |

|

Externality dimension (L x W x H) |

1000 x 750 x 1200 mm |

1320 x 1185 x 1380mm |

|

Weight |

750kg |

2000Kg |

|

Power |

~380V 50Hz 1.5kW |

~380V 50Hz 3kW |