Plastic Sheet Production Line 600mm 3

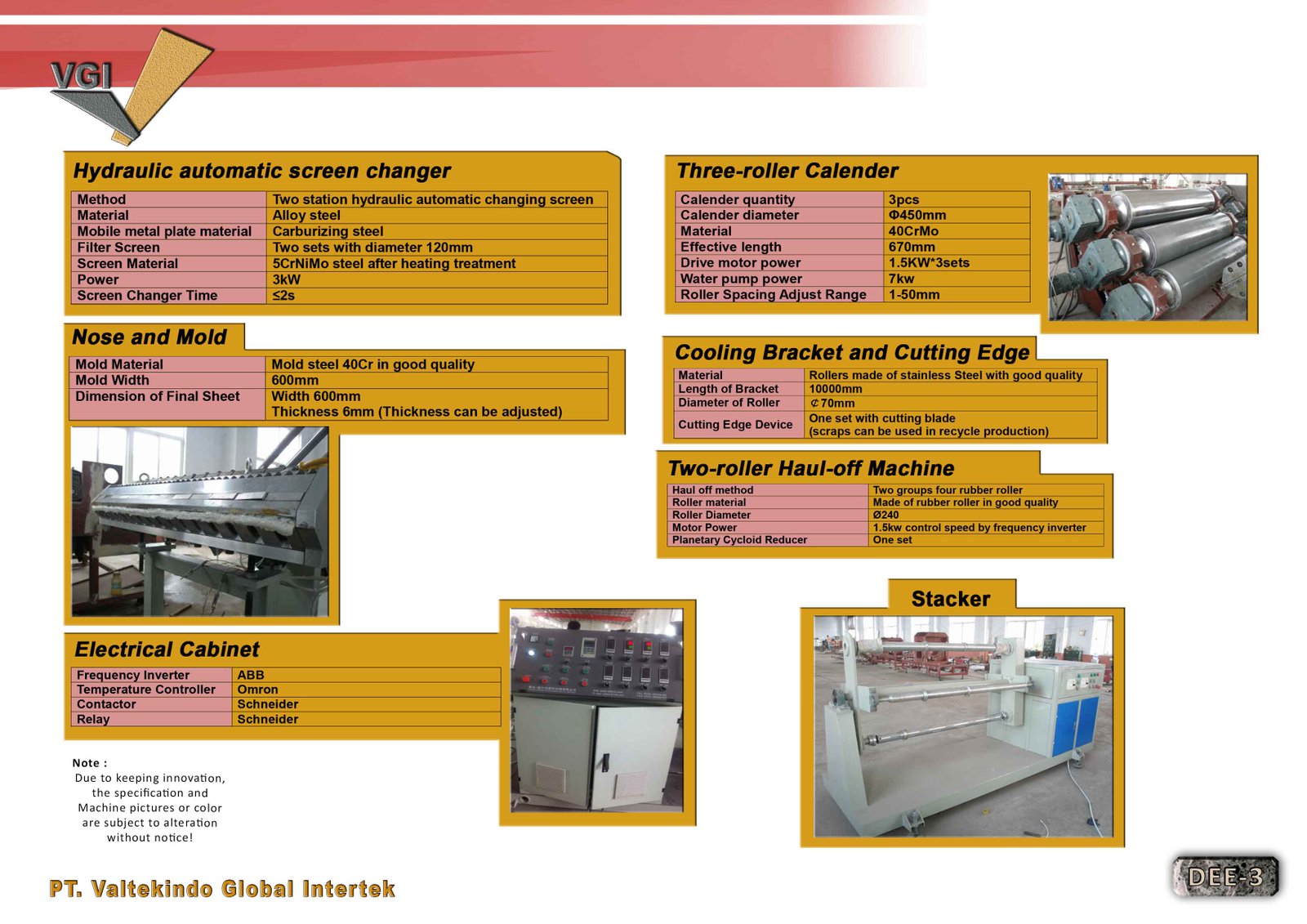

Hydraulic

automatic screen changer

|

Method |

Two Station hydraulic automatic changing screen |

|

Material |

Alloy Steel |

|

Mobile metal plate material |

Carburizing Steel |

|

Filter Screen |

Two sets with diameter 120mm |

|

Screen Material |

5CrNiMo steel after heating treatment |

|

Power |

3kW |

|

Screen Changer Time |

≤2s |

Nose

and Mold

|

Mold Material |

Mold steel 40Cr in good quality |

|

Mold Width |

600mm |

|

Dimension |

Width 600mm Thickness 6mm (Thickness can be adjusted |

Electrical

Cabinet

|

Frequency Inverter |

ABB |

|

Temperature Controller |

Omron |

|

Contactor |

Schneider |

|

Relay |

Schneider |

Three-roller

Calendar

|

Calendar quantity |

3pcs |

|

Calendar diameter |

ȼ450mm |

|

Material |

40CrMo |

|

Effective length |

670mm |

|

Drive motor power |

1.5KW*3sets |

|

Water pump power |

7kw |

|

Roller Spacing Adjust range |

1-50mm |

Cooling

Bracket and Cutting Edge

|

Material |

Rollers made of stainless Steel with good quality |

|

Length of Bracket |

10000mm |

|

Diameter of Roller |

ȼ70mm |

|

Cutting Edge Device |

One set with cutting blade (Scraps can be used in recycle production) |

Two-roller

Haul-off Machine

|

Haul off method |

Two groups four rubber roller |

|

Roller material |

Made of rubber roller in good quality |

|

Roller Diameter |

Ø240 |

|

Motor Power |

1.5kw control speed by frequency inverter |

|

Planetary Cycloid Reducer |

One set |