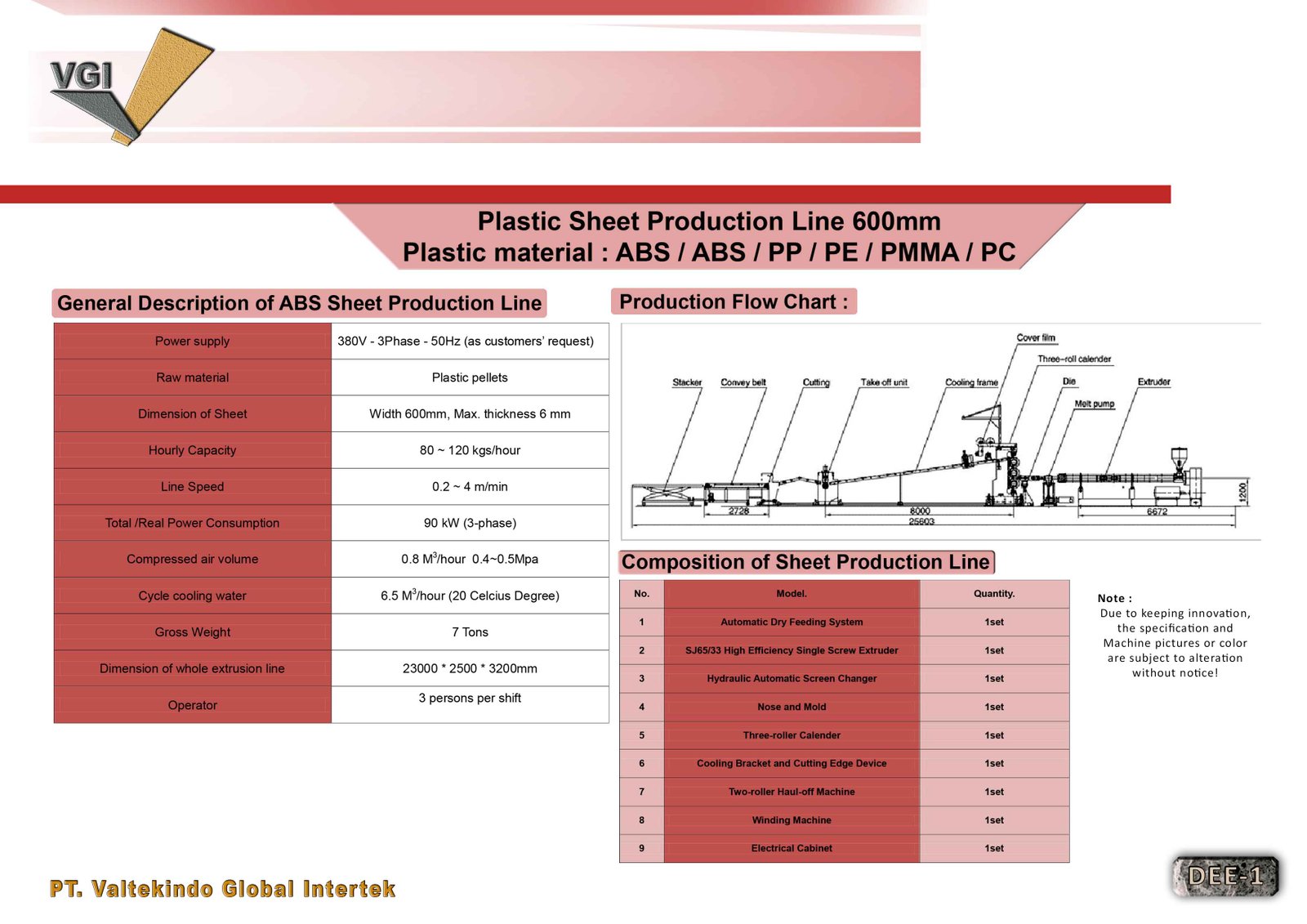

Plastic Sheet Production Line 600mm 1

General

Description of ABS Sheet Production Line

|

Power supply |

380 – 3Phase – 50Hz (as customers’ request) |

|

Raw material |

Plastic pellets |

|

Dimension of sheet |

Width 600mm, Max. thickness 6 mm |

|

Hourly Capacity |

80 ~ 120 kgs/hour |

|

Line Speed |

0.2 ~4 m/min |

|

Total /real Power Consumption |

90 kW (3-phase) |

|

Compressed air volume |

0.8 M3/hour 0.4.5Mpa |

|

Cycle cooling water |

6.5 M3/hour (20 celcius Degree) |

|

Gross Weight |

7 Tons |

|

Dimension of whole extrusion line |

23000 * 2500 * 3200mm |

|

Operator |

3 persons per shift |

Composition

of Sheet Production Line

|

No |

Model |

Quantity |

|

1 |

Automatic Dry Feeding system |

1set |

|

2 |

SJ65/33 High Efficiency Single screw Extruder |

1 set |

|

3 |

Hydraulic Automatic Screen Changer |

1set |

|

4 |

Nose and Mold |

1set |

|

5 |

Three-roller calendar |

1set |

|

6 |

Cooling Bracket and Cutting Edge Device |

1set |

|

7 |

Two-roller haul-off Machine |

1set |

|

8 |

Winding Machine |

1set |

|

9 |

Electrical Cabinet |

1set |