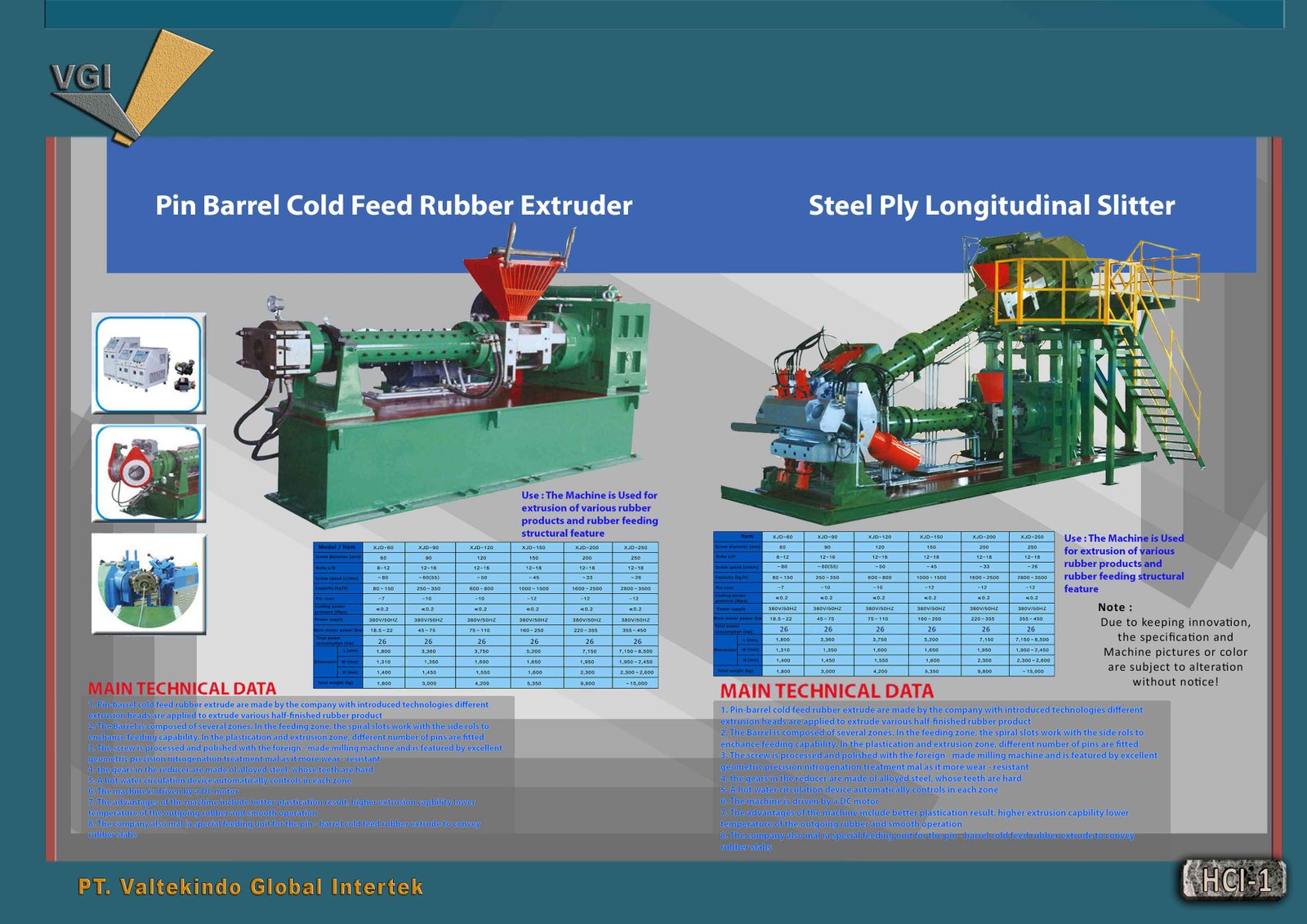

Pin Barrel Extruder Steel Ply Longitudinal Slitter

Pin barrel cold

rubber extruder

MAIN TECHNICAL DATA

1.

Pin-barrel cold

feed rubber extrude are made by the company with introduce technology different

extrusion heads are applied to extrude various half-finished rubber product

2.

The barrel is

composed of several zones. In the feeding zone, the spiral slots work with the

side rolls to enchanted feeding capability. In the plastic and extrusion zone,

different number of pins are fitted

3.

The screw is

processed and polished with the foreign-made milling machine and is featured by

excellent geometric precision nitrogen treatment mal as it more wear-resistant

4.

The gears in the

reducer are made oil alloyed steel, whose teeth are hard

5.

A hot water

circulation device automatically controls in each zone

6.

The machine is

driven by a DC motor

7.

The advantages of

the machine include better plastic result, higher extrusion capability lower

temperature of the outgoing rubber and smooth operation

8.

Rubber company

also mal (a special feeding unit for the pin-barrel cold feed rubber extrude to

convey rubber slabs)

Steel Ply

Longitudinal Slitter

MAIN TECHNICAL DATA

1.

Pin-barrel cold

feed rubber extrude are made by the company with introduce technology different

extrusion heads are applied to extrude various half-finished rubber product

2.

The barrel is

composed of several zones. In the feeding zone, the spiral slots work with the

side rolls to enchanted feeding capability. In the plastic and extrusion zone,

different number of pins are fitted

3.

The screw is

processed and polished with the foreign-made milling machine and is featured by

excellent geometric precision nitrogen treatment mal as it more wear-resistant

4.

The gears in the

reducer are made oil alloyed steel, whose teeth are hard

5.

A hot water

circulation device automatically controls in each zone

6.

The machine is

driven by a DC motor

7.

The advantages of

the machine include better plastic result, higher extrusion capability lower

temperature of the outgoing rubber and smooth operation

8.

Rubber company

also mal (a special feeding unit for the pin-barrel cold feed rubber extrude to

convey rubber slabs)