Pictures Show5

Working

Principle

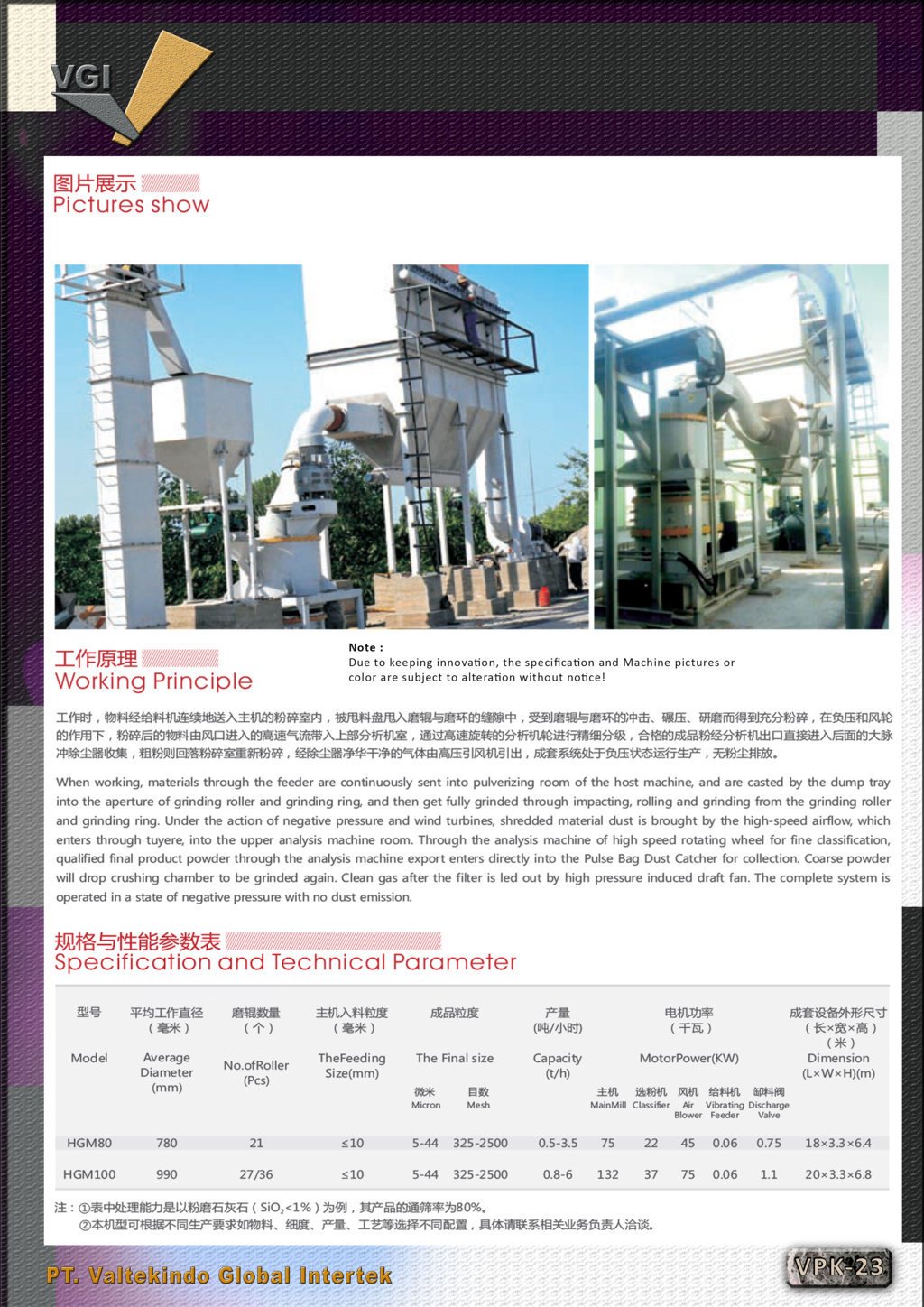

When working, materials through the feeder are continuously sent into pulverizing room of the host machine, and are casted by the dump tray into the aperture of grinding roller and grinding ring, and then get fully grinded through impacting, rolling and grinding from the grinding roller and grinding ring. Under the action of negative pressure and wind turbines, shredded material dust is brought by the high-speed airflow, which enters through tuber, into the upper analysis machine room. Through the analysis machine of high speed rotating wheel for the classification. Qualified final product powder through the analysis machine export enters directly into the Pulse Bag Dust Cather Catcher for collection. Coarse powder will drop crushing chamber to be grinded again. Clean gas after the filter is led out by high pressure included draft fan. The complete system is operated in a state of negative pressure with no dust emission.

Specification and Technical

Parameter

|

Model |

Average

Diameter (mm) |

No. of

Roller (Pcs) |

The

Feeding Size (mm) |

The

Final Size |

Capacity

(t/h) |

Motor

Power (kW) |

Dimension

(LxWxH)(m) |

|||||

|

Micron |

Mesh |

Main

Mill |

Classifier |

Air

Blower |

Vibrating

Feeder |

Discharge

Valve |

||||||

|

HGM80 |

780 |

21 |

≤10 |

5-44 |

325-2500 |

0.5-3.5 |

75 |

22 |

45 |

0.06 |

0.75 |

18x3.3x6.4 |

|

HGM100 |

990 |

27/36 |

≤10 |

5-44 |

325-2500 |

0.8-6 |

132 |

37 |

75 |

0.06 |

1.1 |

20x3.3x6.8 |