Pembuat biji karet 100Kgs per hour 4

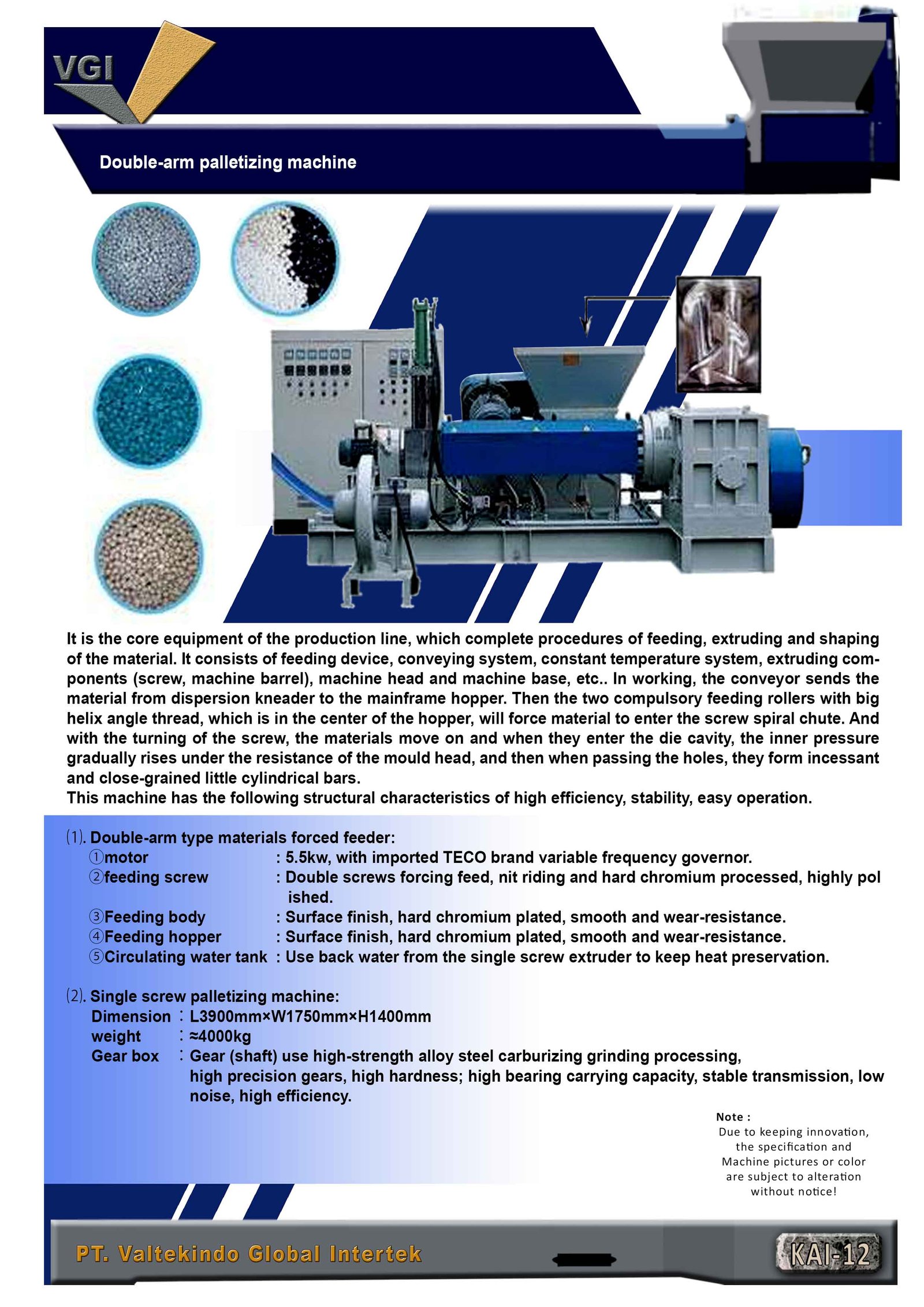

Double-arm Palletizing Machine

It is the core equipment of the production line, which complete procedures of feeding, extruding and shaping of the material. It consists of feeding device, conveying system, constant temperature system, extruding components (screw, machine barrel), machine head and machine base, etc.. In working, the conveyor sends the material from dispersion kneader to the mainframe hopper. Then the two compulsory feeding rollers with big helix angle thread, which is in the center of the hopper, will force material to enter the screw spiral chute. And with the turning of the screw, the materials move on and when they enter the die cavity, the inner pressure gradually rises under the resistance of the mould head, and then when passing the holes, they form incessant and close-grained little cylindrical bars.

This machine has the following structural characteristics of high efficiency, stability, easy operation.

1. Double-arm type materials forced feeder:

Motor : 5.5kw, with imported TECO brand variable frequency governor.

Feeding screw : Double screws forcing feed, nit riding and hard chromium processed, highly polished.

Feeding body : Surface finish, hard chromium plated, smooth and wear-resistance.

Feeding hopper : Surface finish, hard chromium plated, smooth and wear-resistance.

Circulating water tank : Use back water from the single screw extruder to keep heat preservation.

2.Single screw palletizing machine:

Dimension:L3900mm×W1750mm×H1400mm

Weight :≈4000kg

Gear box: Gear (shaft) use high-strength alloy steel carburizing grinding processing, high precision gears, high hardness; high bearing carrying capacity, stable transmission, low noise, high efficiency.