New Salt Bath Vulcanization Production Line (LCM) 2

LCM

Environmental protection, high efficient, energy conservation and safety of LCM salt-bath vulcanization system for rubber profiles.

The characteristics of LCM Technology:

Compared with other rubber vulcanization

technologies, such as microwave vulcanization (UHF), the characteristics of LCM

system are outstanding. It is mainly manifested in its excellent processing

quality, high vulcanization speed and wide practicability.

1. With excellent heat transfer

performance due to curing bath. Vulcanization of rubber profiles is complete

and uniform throughout the section.

2. During vulcanization, the rubber

profile with high density salt bath is subjected to uniform pressure, and the

vulcanization deformation is very small.

3. Salt bath inhibited the formation of

low supplied zone on the surface of rubber, and the rubber treated by LCM had

good mechanical properties.

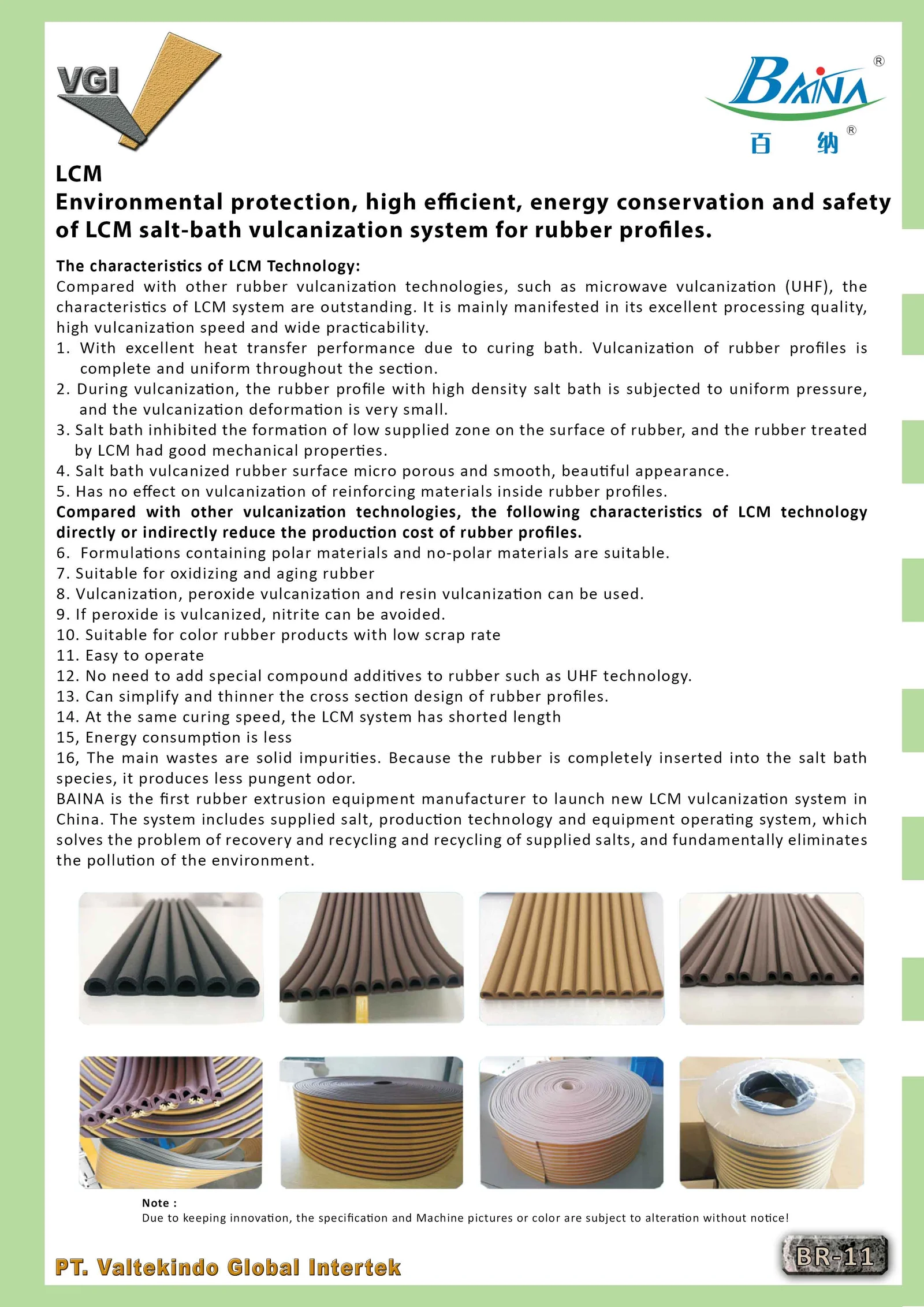

4. Salt bath vulcanized rubber surface

micro porous and smooth, beautiful appearance.

5. Has no effect on vulcanization of reinforcing materials inside rubber profiles.

Compared

with other vulcanization technologies, the following characteristics of LCM

technology directly or indirectly reduce the production cost of rubber

profiles.

6.

Formulations containing polar materials and no-polar materials are

suitable.

7. Suitable for oxidizing and aging

rubber

8. Vulcanization, peroxide vulcanization

and resin vulcanization can be used.

9. If peroxide is vulcanized, nitrite

can be avoided.

10. Suitable for color rubber products

with low scrap rate

11. Easy to operate

12. No need to add special compound

additives to rubber such as UHF technology.

13. Can simplify and thinner the cross

section design of rubber profiles.

14. At the same curing speed, the LCM

system has shorted length

15. Energy consumption is less

16. The main wastes are solid

impurities. Because the rubber is completely inserted into the salt bath

species, it produces less pungent odor.

BAINA is the first rubber extrusion

equipment manufacturer to launch new LCM vulcanization system in China. The

system includes supplied salt, production technology and equipment operating

system, which solves the problem of recovery and recycling and recycling of

supplied salts, and fundamentally eliminates the pollution of the environment.