Laminating Machines

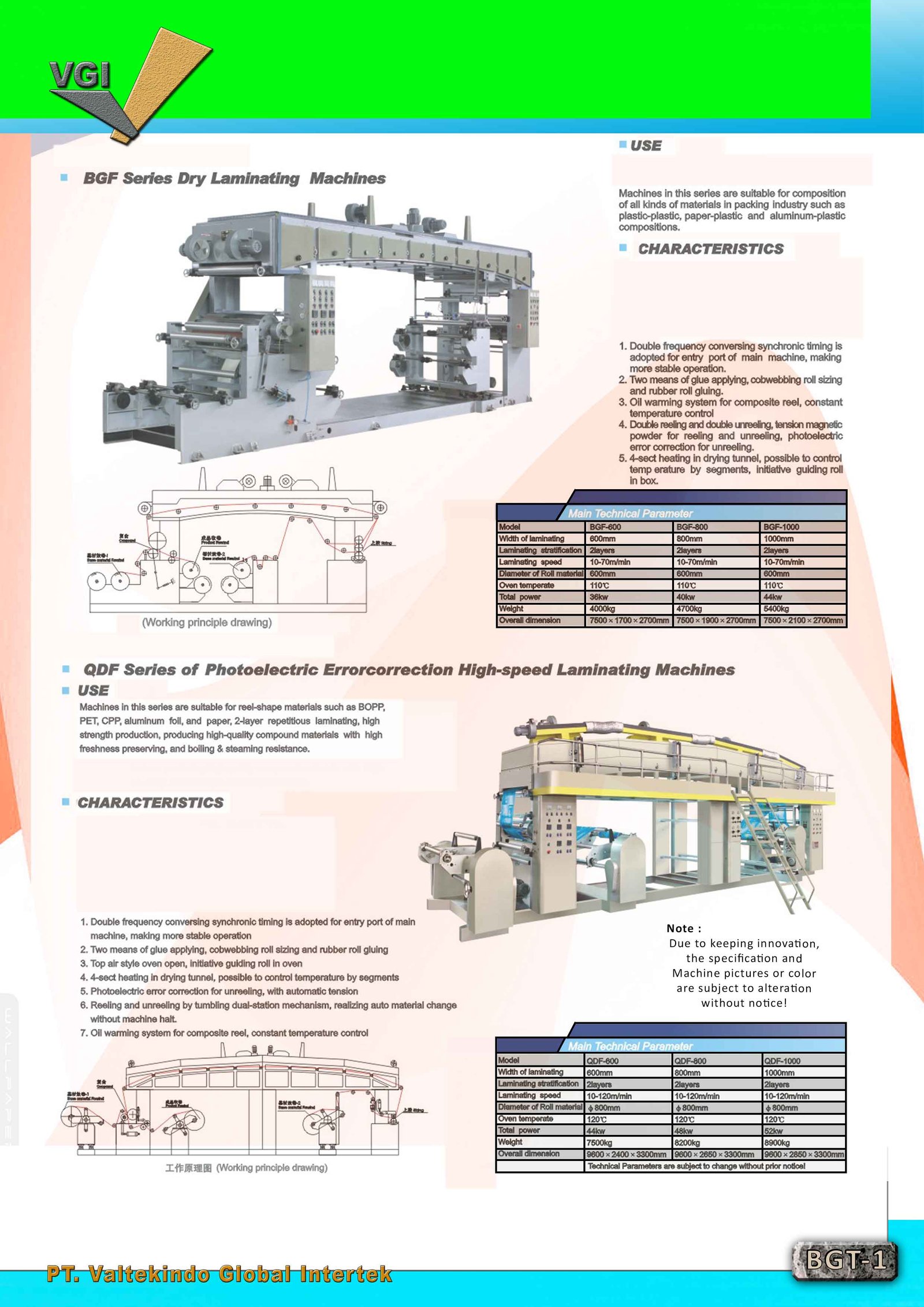

· BGF Series Dry Laminating Machines

USE

Machine in this series are suitable for composition of all kinds of materials in packing industry such as plastic-plastic, paper-plastic and aluminum-plastic compositions.

CHARACTERISTICS

1. Double frequency conversing synchronic timing is adopted for entry port main machine, making more stable operation

2. Two means of glue applying, cob webbing roll sizing and rubbers roll gluing

3. Oil warming system for composite reel, constant temperature control

4. Double reeling and double unreeling, tension magnetic powder for reeling and unreeling, photoelectric error correction for unreeling

5. 4-sect heating in drying tunnel, possible to control temperature by segments, initiative guiding roll in box

MAIN TECHNICAL PARAMETER

Model | BGF-600 | BGF-800 | BGF-1000 |

Width of laminating | 600mm | 800mm | 1000mm |

Laminating stratification | 2 layers | 2 layers | 2 layers |

Laminating speed | 10-70m/min | 10-70m/min | 10-70m/min |

Diameter of Roll material | 600mm | 600mm | 600mm |

Oven temperate | 110áµ’C | 110áµ’C | 110áµ’C |

Total power | 36kw | 40kw | 44kw |

Weight | 4000kg | 4700kg | 5400kg |

Overall dimension | 7500x1700x2700mm | 7500x1900x2700mm | 7500x2100x2700mm |

· QDF Series of Photoelectric Error correction High-speed Laminating Machines

USE

Machines in this series are suitable for reel-shape materials such as BOPP, PET, CPP, aluminum foil, and paper, 2-layer repetitious laminating, high strength production, producing high-quality compound materials with high freshness preserving, and boiling & steaming resistance.

CHARACTERISTICS

1. Double frequency conversing synchronic timing is adopted for entry port main machine, making more stable operation

2. Two means of glue applying, cob webbing roll sizing and rubbers roll gluing

3. Top air style oven open, initiative guiding roll in oven

4. 4-sect heating in drying tunnel, possible to control temperature by segments

5. Photoelectric error correction for unreeling, with automatic tension

6. Reeling and unreeling by tumbling dual-station mechanism, realizing auto material change without machine halt

7. Oil warming system for composite reel, constant temperature control

MAIN TECHNICAL PARAMETER

Model | QDF-600 | QDF-800 | QDF-1000 |

Width of laminating | 600mm | 800mm | 1000mm |

Laminating stratification | 2 layers | 2 layers | 2 layers |

Laminating speed | 10-120m/min | 10-120m/min | 10-120m/min |

Diameter of Roll material | ɸ 800mm | ɸ 800mm | ɸ 800mm |

Oven temperate | 120áµ’C | 120áµ’C | 120áµ’C |

Total power | 44kw | 48kw | 52kw |

Weight | 7500kg | 8200kg | 8900kg |

Overall dimension | 9600x2400x3300mm | 9600x2650x3300mm | 9600x2850x3300mm |