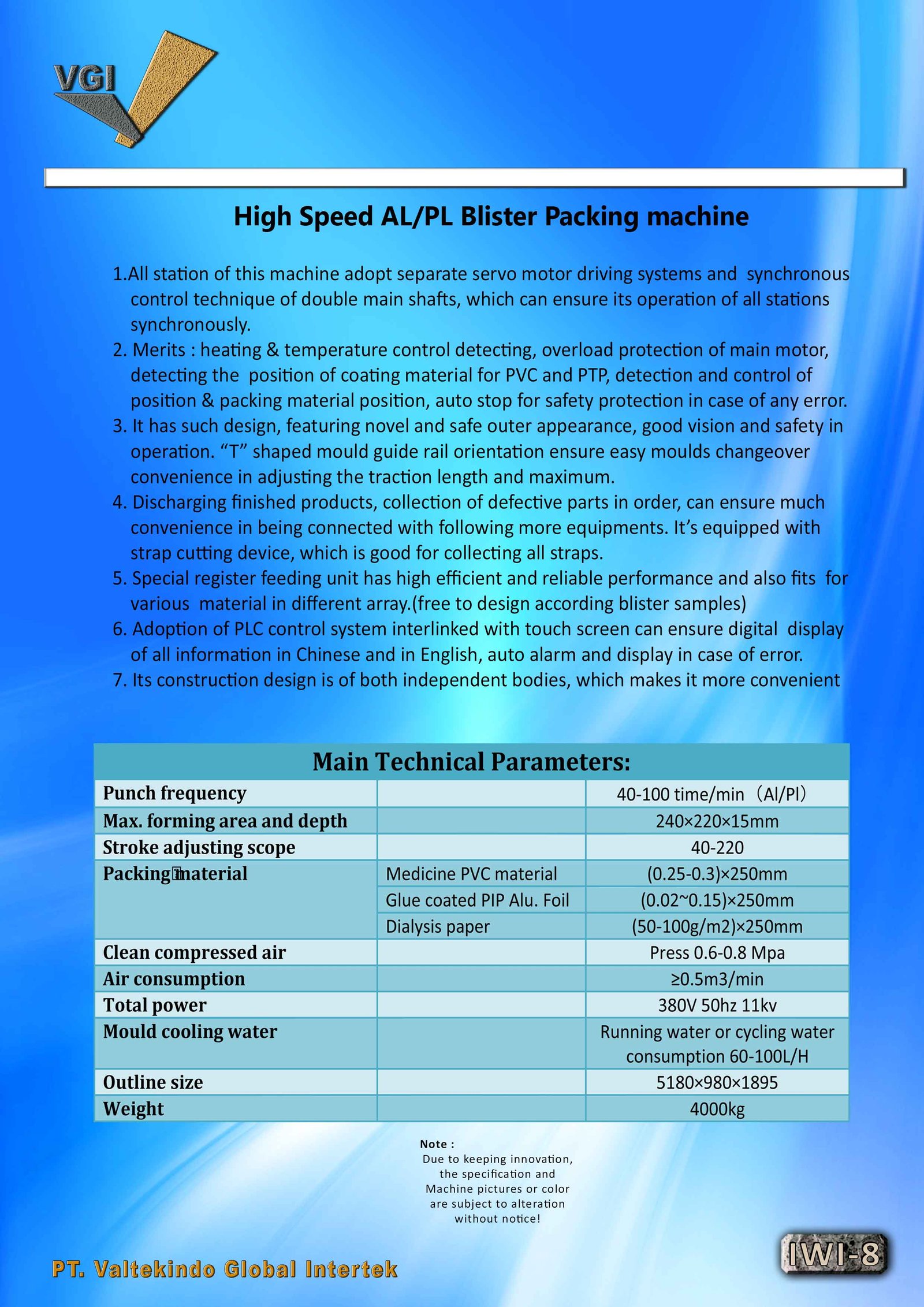

High Speed AL/PL Blister Packing Machine

High

Speed AL/PL Blister Packing machine

1.All station of

this machine adopt separate servo motor driving systems and synchronous control technique of

double main shafts, which can ensure its

operation of all stations synchronously.

2. Merits : heating

& temperature control detecting, overload protection of main motor, detecting

the position of

coating material for PVC and PTP, detection

and control of position & packing material position, auto stop for

safety protection in case of any error.

3. It has such

design, featuring novel and safe outer appearance, good vision and safety in operation.

“T†shaped

mould guide rail orientation ensure easy

moulds changeover convenience in adjusting the traction length and

maximum.

4. Discharging

finished products, collection of defective parts in order, can ensure much convenience

in being

connected with following more equipments.

It’s equipped with strap cutting device, which is good for collecting all

straps.

5. Special register

feeding unit has high efficient and reliable performance and also fits for various

material in

different array.(free to design according

blister samples)

6. Adoption of PLC

control system interlinked with touch screen can ensure digital display of all information in

Chinese and in English, auto alarm and

display in case of error.

7. Its construction

design is of both independent bodies, which makes it more convenient

Main

Technical Parameters :

|

Punch

frequency |

|

40-100 time/min (Al/Pl) |

|

Max.

forming area and depth |

|

240x220x15mm |

|

Stroke

adjusting scope |

|

420-220 |

|

Packing

material |

Medicine

PVS Material |

(0.25-0.3)x250mm |

|

Glue

coated PIP Alu. Foil |

(0.02~0.15)x250mm |

|

|

Dialysis

paper |

(50-100g/m2)x250mm |

|

|

Clean

compressed air |

|

Press 0.6-0.8 MPa |

|

Air

consumption |

|

≥0.05m3/min |

|

Total

power |

|

380V 50Hz 11kW |

|

Mould

cooling water |

|

Running water or cycling water

consumption 60-100L/H |

|

Outline

size |

|

5180x980x1895 |

|

Weight

|

|

4000Kg |