High Production Carding Machine

Main

Specifications

|

1. Applicable range 2. Feeding weight 3. Working width 4. Total draft multiple 5. Slivers grams 6. Max. delivery speed 7. Actual max. production 8. Licker-in working dia. 9. Cylinder working dia. 10. Cylinder working speed. 11. Doffer working dia. 12. Doffer working speed. 13. Revolving flats no.(working/total) 14. Flats speed 15. Stationary flats No 16. Web purifier 17. Coiler type 18. Sliver can specification 19. Continuous air suction amount per set 20. Resistant at suction port 21. Total installed power 22. Overall size (L x W x H) 23. Machine weight |

: Fiber length: 22-76mm, 100% cotton, manmade Fibers or Blending. : 350-1000g/m : 1000mm : 70-130 : 3.5-6.5g/m : 240m/min : 93kg/h : 250mm : 1290mm : 360-500rpm : 706mm : 10-65rpm : 30/82 : 133-278mm/min : front 4 rear 7 : front 1 rear 2 : manual or revolving type 3- position auto can changer : φ600 x 900, φ600 x 1100 : 3500~4000m³h : ≥-950 Pa : 10.16kW : 3800 x 1975 x 2160 (collier excluded) : 7000Kg |

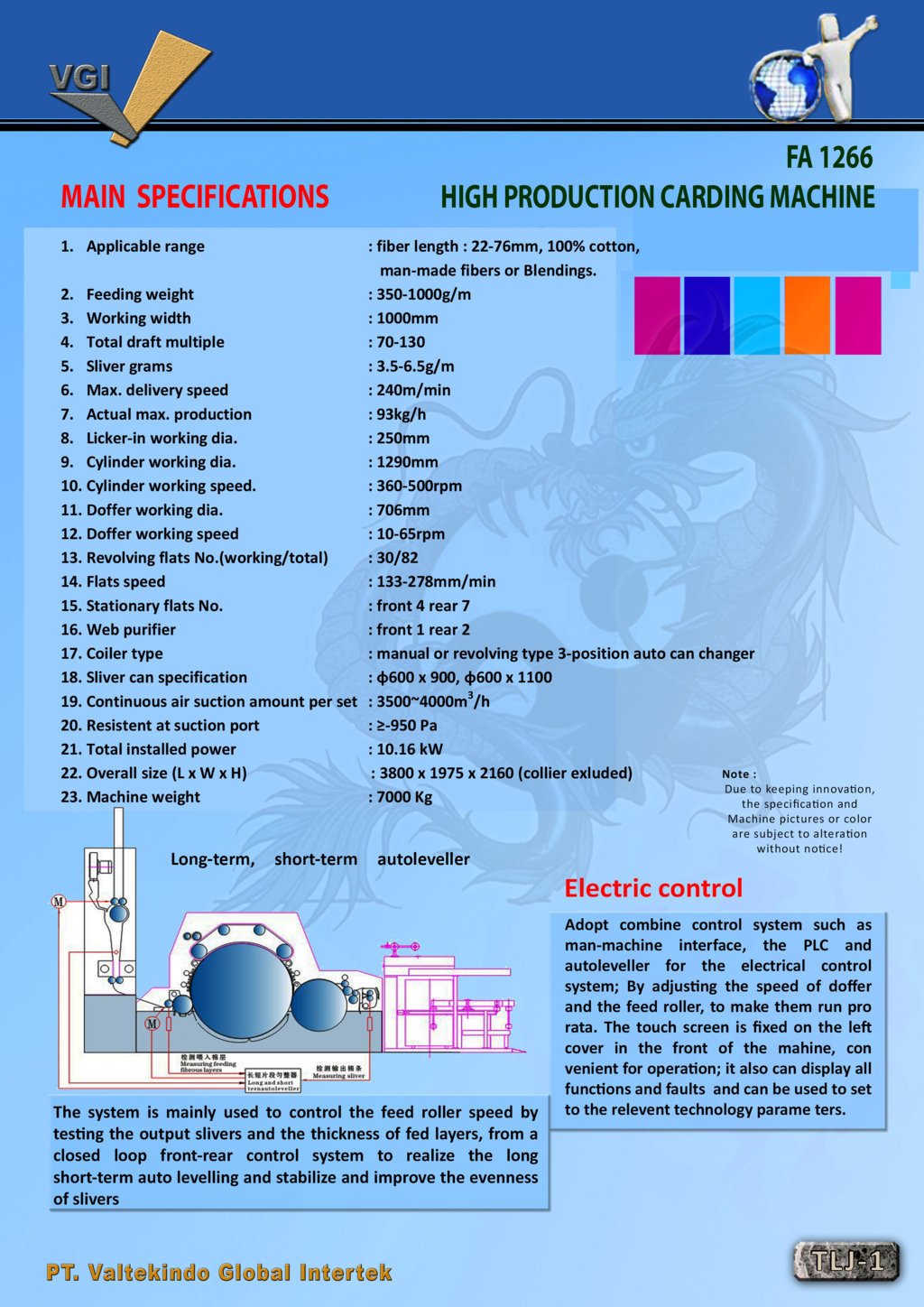

Long term, short-term, autoleveller

Electric control

Adopt combine control system such as man-machine interface, the PLC and autoleveller for the electrical control system: by adjusting the speed of doffer and the feed roller, to make them run pro rata. The touch screen is fixed on the left cover in the front of the machine, convenient for operation; it also can display all functions and fault and can be used to set t the relevant technology parameters.

The system is mainly used to control the feed roller speed by testing the output slivers and the thickness of fed layers, from a closed loop front-rear control system to realize the long short-term auto leveling and stabilize improve the evenness of slivers