Fully Automatic Block

Fully

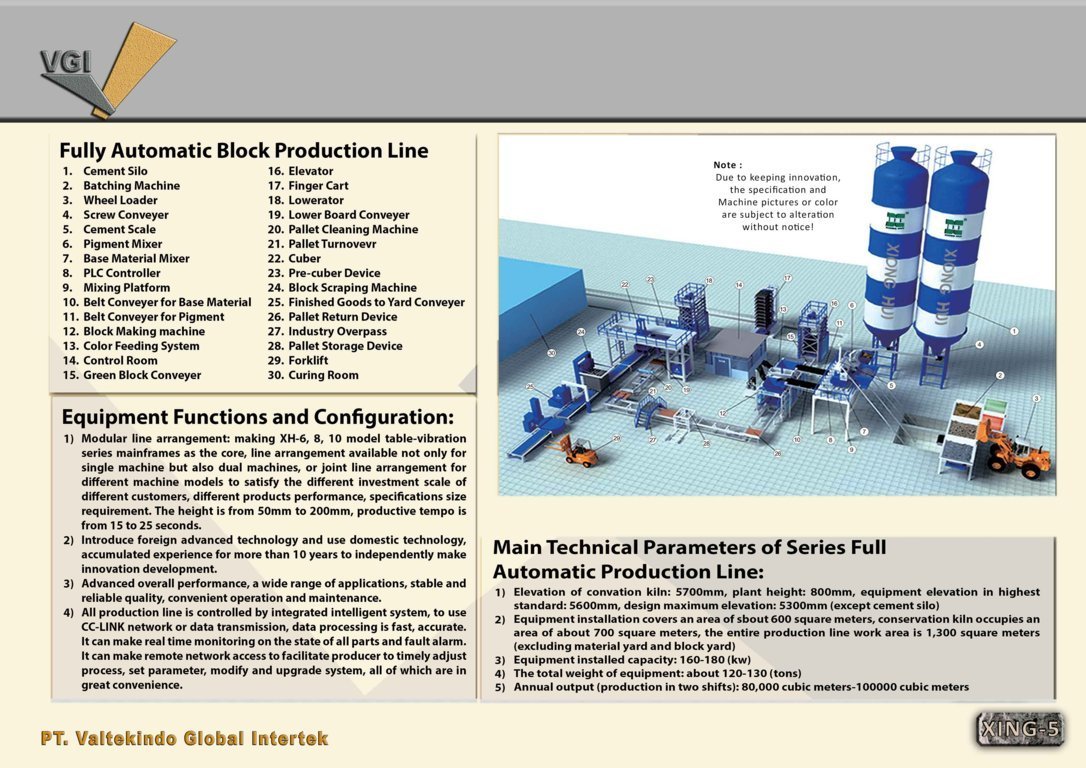

Automatic Block Production Line

1.

Cement

Silo

2. Batching Machine

3. Wheel Loader

4. Screw Conveyor

5. Cement Scale

6. Pigment Mixer

7. Base Material Mixer

8. PLC Controller

9. Mixing Platform

10. Belt Conveyer For base Material

11. Belt conveyer for base Pigment

12. Block Making machine

13. Color Feeding System

14. Control Room

15. Green Block Conveyer

16. Elevator

17. Finger Cart

18. Lower actor

19. Lower Board Conveyer

20. Pallet Cleaning Machine

21. Pallet Turnoverr

22. Cuber

23. Pre-cuber Device

24. Block Scraping Machine

25. Finished Goods to Yard Conveyer

26. Pallet Return Device

27. Industry Overpass

28. Pallet Storage Device

29. Forklift

30. Curing Room

Equipment Functions

and Configuration :

1.

Modular

line arrangement : making XH-6, 8, 10 model table-vibration series mainframes

as the core, line arrangement available not only for single machine but also

dual machines, or joint line arrangement for different customers, different

products performance, specifications size requirement. The height is from 50mm

to 200mm, productive tempo is from 15 to 25 seconds.

2. Introduce foreign advanced

technology and use domestic technology, accumulated experience for more than 10

years to independently make innovation development.

3. Advanced overall performance, a

wide range of applications, stable and reliable quality, convenient operation

and maintenance.

4.

All

production line is controlled by integrated intelligent system, to use CC-LINK

network or data transmission, data processing is fast, accurate. It can make

real time monitoring on the state of all parts and fault alarm. It can make

remote network access to facilitate producer to timely adjust process, set

parameter, modify and upgrade system, all of which are in great convenience.

Main Technical

Parameters of Series Full Automatic Production Line :

1.

Elevation

of convation klin : 5700mm, plant height ; 800mm, equipment elevation in

highest standard : 5600mm, design maximum elevation : 5300mm (except cement

silo)

2. Equipment installation covers an

area of shout 600 square meters, conservation klin occupies an area of about

700 square meters, the entrie production line work area is 1,300 square meters

(excluding material yard and block yard)

3. Equipment installed capacity :

160 – 180 (kW)

4. The total weight of equipment :

about 120 – 130 (tons)

5. Annual output (production in two

shifts) : 80,000 cubic meters – 100000 cubic meters