Double color film Blowing Machine & Mini Film Blowing

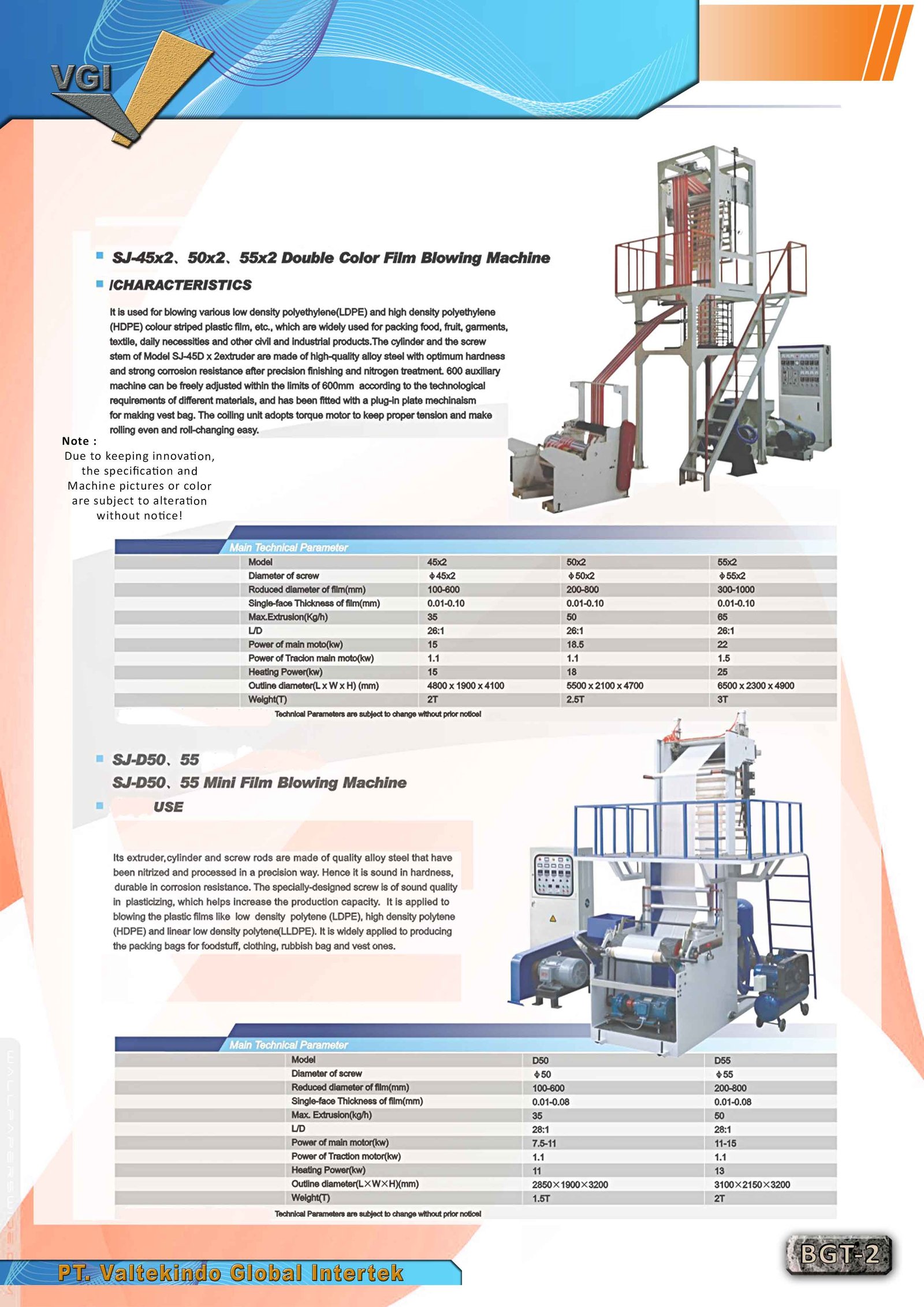

SJ-45x2,

50x2, 55x2 Double Color Film Blowing Machine

CHARACTERISTICS

It used for blowing various low density polyethylene (LDPE) and high density polyethylene (HDPE) color striped plastic film, etc, which are widely used for packing food, fruit, garments, textile, daily necessities and other civil and industrial products. The cylinder and the screw stem of Model SJ-45D x 2extruder are made of high-quality alloy steel with optimum hardness and strong corrosion resistance after precision finishing and nitrogen treatment. 600 auxiliary machine can be freely adjusted within the limits of 600mm according to the technological requirements of different materials, and has been fitted with a plug-in plate mechanism for making vest bag. The cooling unit adopts torque motor to keep proper tension and make rolling even and roll-changing easy

|

Model |

45x2 |

50x2 |

55x2 |

|

Diameter

of screw |

ɸ45x2 |

ɸ50x2 |

ɸ55x2 |

|

Reduced

diameter of film (mm) |

100-600 |

200-800 |

300-1000 |

|

Single-face

Thickness of film (mm) |

0.01-0.10 |

0.01-0.10 |

0.01-0.10 |

|

Max.

Extrusion (Kg/h) |

35 |

50 |

65 |

|

L/D |

26:1 |

26:1 |

26:1 |

|

Power of

main motor (kw) |

15 |

18.5 |

22 |

|

Power of

traction main motor (kw) |

1.1 |

1.1 |

1.5 |

|

Heating

power (kw) |

15 |

18 |

25 |

|

Outline

diameter (LxWxH) |

4800x1900x4100 |

5500x2100x4700 |

6500x2300x4900 |

|

Weight

(T) |

2T |

2.5T |

3T |

SJ-D50,

55 Mini Film Blowing Machine

USE:

Its extruder, cylinder and screw rods are made of quality alloy steel that have been nitrized and processed in a precision way. Hence it is sound hardness, durable in corrosion resistance. The specially-designed screw is of sound quality in plasticizing, which helps increase the production capacity. It is applied to blowing the plastic films like low density polytene (LDPE), high density polytene (HDPE) and linear low density polytene (LLDPE). It is widely applied to producing the packing bags for foodstuff, clothing, rubbish bag and vest ones

|

Model |

D50 |

D55 |

|

Diameter

of screw |

ɸ50 |

ɸ55 |

|

Reduced

diameter of film (mm) |

100-600 |

200-800 |

|

Single-face

Thickness of film (mm) |

0.01-0.8 |

0.01-0.8 |

|

Max.

Extrusion (Kg/h) |

35 |

50 |

|

L/D |

28:1 |

28:1 |

|

Power of

main motor (kw) |

7.5-11 |

11-15 |

|

Power of

traction main motor (kw) |

1.1 |

1.1 |

|

Heating

power (kw) |

11 |

13 |

|

Outline

diameter (LxWxH) |

2850x1900x3200 |

3100x2150x3200 |

|

Weight

(T) |

1.5T |

2T |