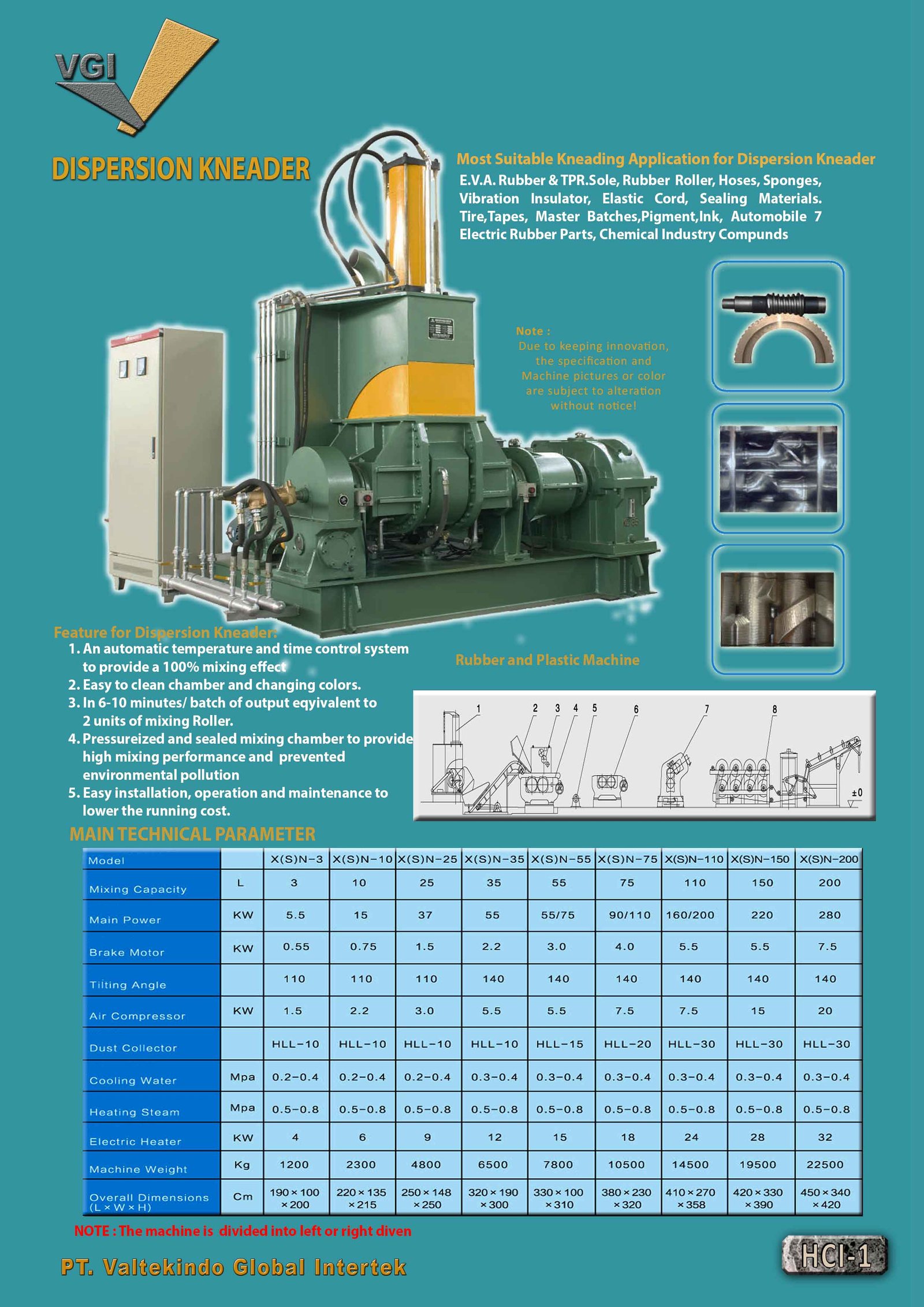

DISPERSION KNEADER

DISPERSION KNEADER

Most suitable kneading

application for dispersion kneader

E.V.A rubber & TPR. Sole, rubber roller, hoses sponges, vibration insulator, elastic cord, sealing materials. Tire, Tapes, Master Batches, Pigment, Ink, Automobile 7 Electric rubber parts, Chemical industry compounds

Features for Dispersion Kneader:

1. An automatic temperature and time control system to provide a 100% mixing effect.

2. Easy to clean chamber and changing colors.

3. In 6-10 minutes/batch of output equivalent to 2 units of mixing roller.

4. Pressurized and sealed mixing chamber to provide high mixing performance and prevented environmental pollution.

5. Easy installation, operation and maintenance to lower the running cost.