Core Filled Snack Food Processing

Core

Filled Snack Food Processing Line

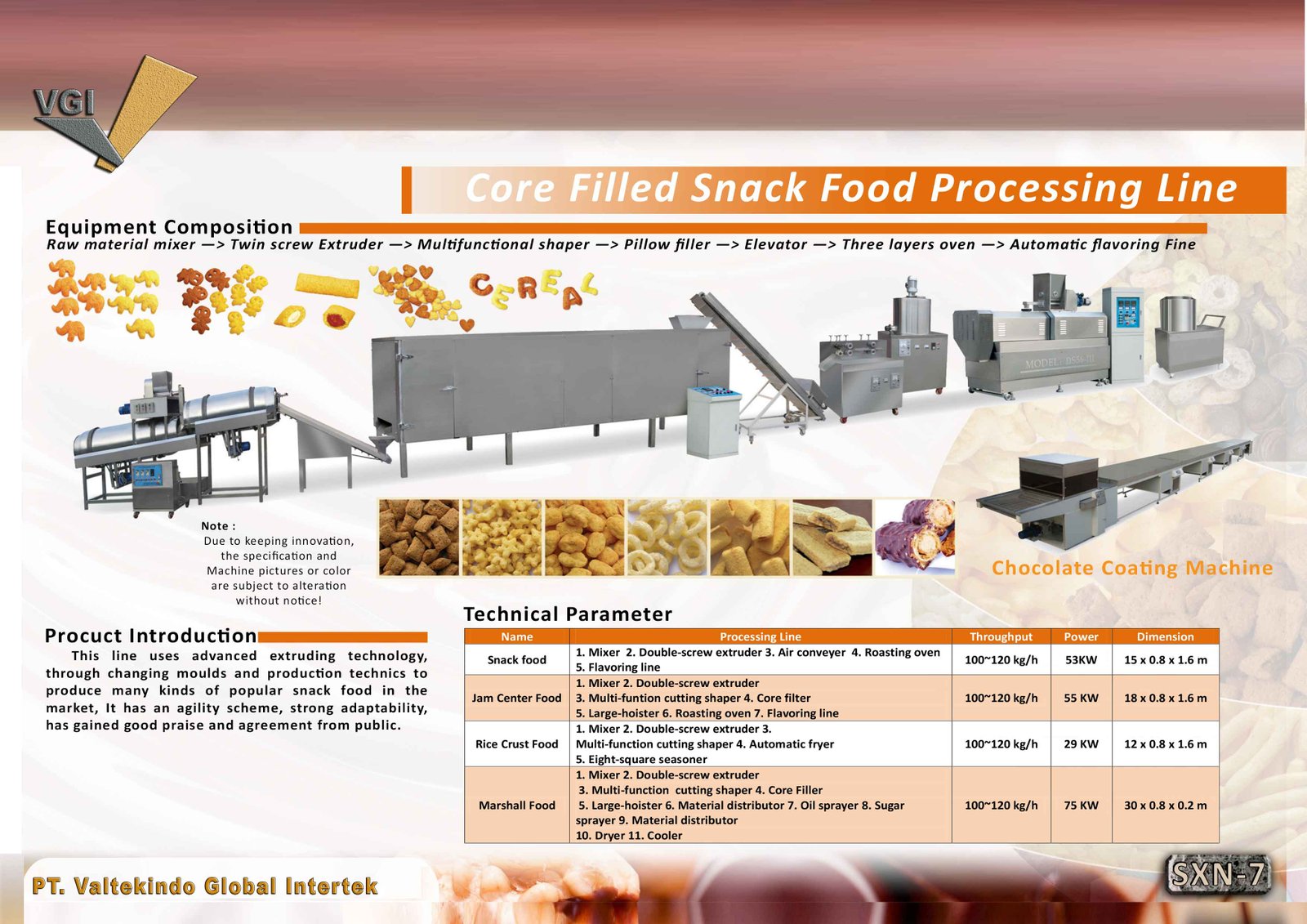

Equipment

Composition

Raw material mixer

—> Twin screw Extruder —> Multifunctional shaper —> Pillow filler

—> Elevator —> Three layers oven —> Automatic flavoring Fine

Procuct

Introduction

This

line uses advanced extruding technology, through changing moulds and production

technics to produce many kinds of popular snack food in the market, It has an

agility scheme, strong adaptability, has gained good praise and agreement from

public.

Technical

Parameter

|

Name |

Processing Line |

Throughput |

Power |

Dimension |

|

Snack Center Food |

1.

Mixer 2.Double-screw extruder 3.Air Conveyor 4. Roasting oven 5.Flavour |

100~120Kg/h |

53kW |

15 x 0.8 x 1.6 m |

|

Jam Center Food |

1.Mixer

2.Double-screw extruder 3.multi function cutting shaper 4.Core filter

5.Large-hoister 6.Roasting oven 7.Flavoring line |

100~120Kg/h |

55kW |

18 x 0.8 x 1.6 m |

|

Rice Crust Food |

1.Mixer

2.Double-screw extruder 3.Multi-function cutting, shaper 4.Automatic friyer

5.Eight-square seasoner |

100~120Kg/h |

29kW |

12 x 0.8 x 1.6 m |

|

Marshall Food |

1.Mixer

2.Double-screw extruder 3.Multi-function cutting shaper 4.Core Filler

5.Large-hoister 6.Material distributor 7.Oil sprayer 8.Sugar sprayer

9.Material distributor 10.Driyer 11.Cooler |

100~120Kg/h |

75kW |

30 x 0.8 x 0.2 m |