Contniuous Carbonization Furnace (Workflow)

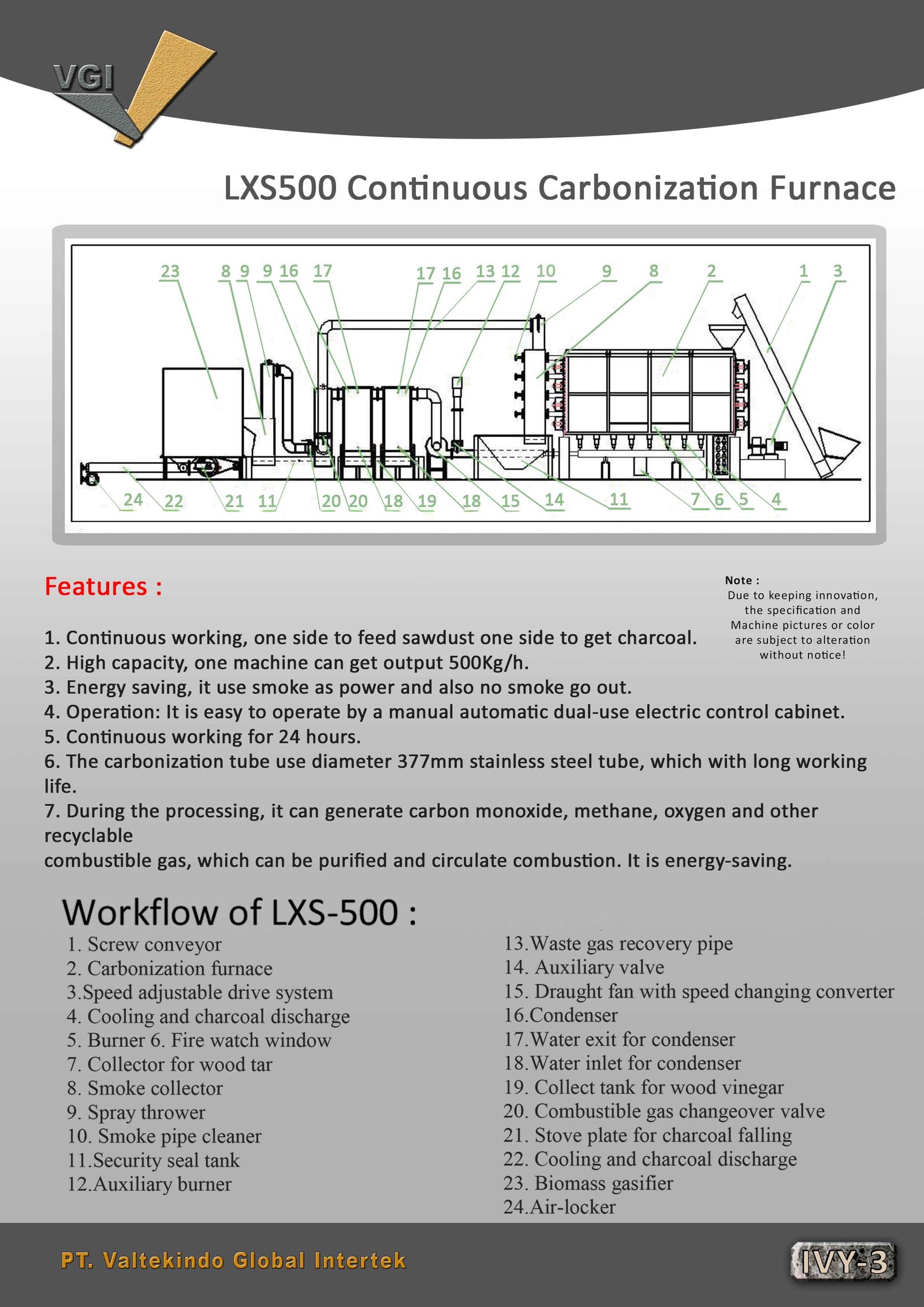

LXS500 Continuous Carbonization Furnace

Features:

1. Continuous working, one side to feed sawdust one side to get charcoal.

2. High capacity, one machine can get output 500Kg/h.

3. Energy saving, it use smoke as power and also no smoke go out.

4. Operation: It is easy to operate by a manual automatic dual-use electric control cabinet.

5. Continuous working for 24 hours.

6. The carbonization tube use diameter 377mm stainless steel tube, which with long working life.

7. During the processing, it can generate carbon monoxide, methane, oxygen and other recyclable combustible gas, which can be purified and circulate combustion. It is energy-saving.

Workflow of LXS-500:

1. Screw conveyor

2. Carbonization furnace

3. Speed adjustable drive system

4. Cooling and charcoal discharge

5. Burner 6 fire watch window

6. Collector for wood tar

7. Smoke collector

8. Smoke pipe cleaner

9. Security seal tank

10. Auxiliary burner

11. Waste gas recovery pipe

12. Auxiliary valve

13. Draught fan with speed changing converter

14. Condenser

15. Water exit for condenser

16. Water inlet for condenser

17. Collect tank for wood vinegar

18. Combustible gas change over valve

19. Stove plate for charcoal falling

20. Cooling and charcoal discharge

21. Biomass gasifier

22. Air-locker