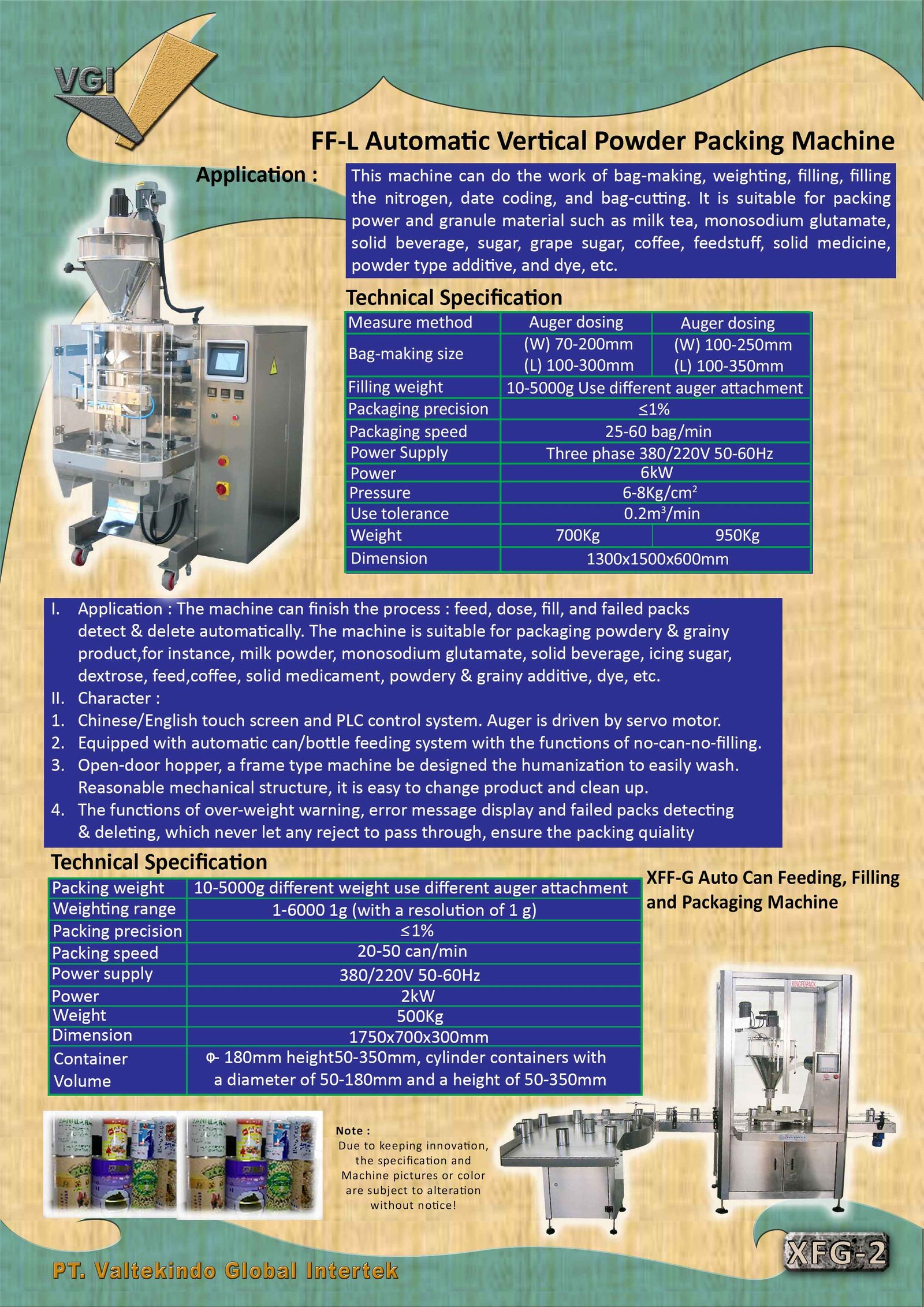

Automatic Vertical Powder Packing Machine

Application :

This machine can do the work of bag-making, weighting, filling, filling the nitrogen, date coding, and bag-cutting. It is suitable for packing power and granule material such as milk tea, monosodium glutamate, solid beverage, sugar, grape sugar, coffee, feedstuff, solid medicine, powder type additive, and dye, etc.

Technical Specification

|

Measure method |

Auger

dosing |

Auger |

|

Bag-making size |

(W)

70-200mm (L)

100-300MM |

(W)

100-250mm (L) 100-350mm |

|

Filling weight |

10-5000g

Use different auger attachment |

|

|

Packaging precision |

≤1% |

|

|

Packaging speed |

25-60

bag/min |

|

|

Power Supply |

Three

phase 380/220V 50-60Hz |

|

|

Power |

6kW |

|

|

Pressure |

6-8Kg/cm2 |

|

|

Use tolerance |

0.2m3/min |

|

|

Weight |

700Kg |

950Kg |

|

Dimension |

1300x1500x600mm |

|

I. Application : The machine can finish the process : feed, dose, fill, and failed packs detect & delete automatically.

The machine is suitable for packaging powdery & grainy product, for instance, milk powder, monosodium

glutamate, solid beverage, icing sugar, dextrose, feed, coffee, solid medicament, powdery & grainy additive, dye,

etc.

II. Character :

1. Chinese/English touch screen and PLC control system. Auger is driven by servo motor.

2. Equipped with automatic can/bottle feeding system with the functions of no-can-no-filling.

3. Open-door hopper, a frame type machine be designed the humanization to easily wash.

Reasonable mechanical structure, it is easy to change product and clean up.

4. The functions of over-weight warning, error message display and failed packs detecting & deleting, which

never let any reject to pass through, ensure the packing quality

Technical Specification

|

Packaging weight |

10-5000g

different weight use different auger attachment |

|

Weight range |

1-6000 1g

(with a resolution of 1g) |

|

Packing precision |

≤1% |

|

Packing speed |

20-50

can/min |

|

Power supply |

380/220V

50-60Hz |

|

Power |

2kW |

|

Weight |

500Kg |

|

Dimension |

1750x700x300mm |

|

Container Volume |

ɸ 180mm

height50-350mm, cylinder containers with a

diameter of 50-180mm and a height of 50-350mm |