Automatic Biscuit Processing

Automatic

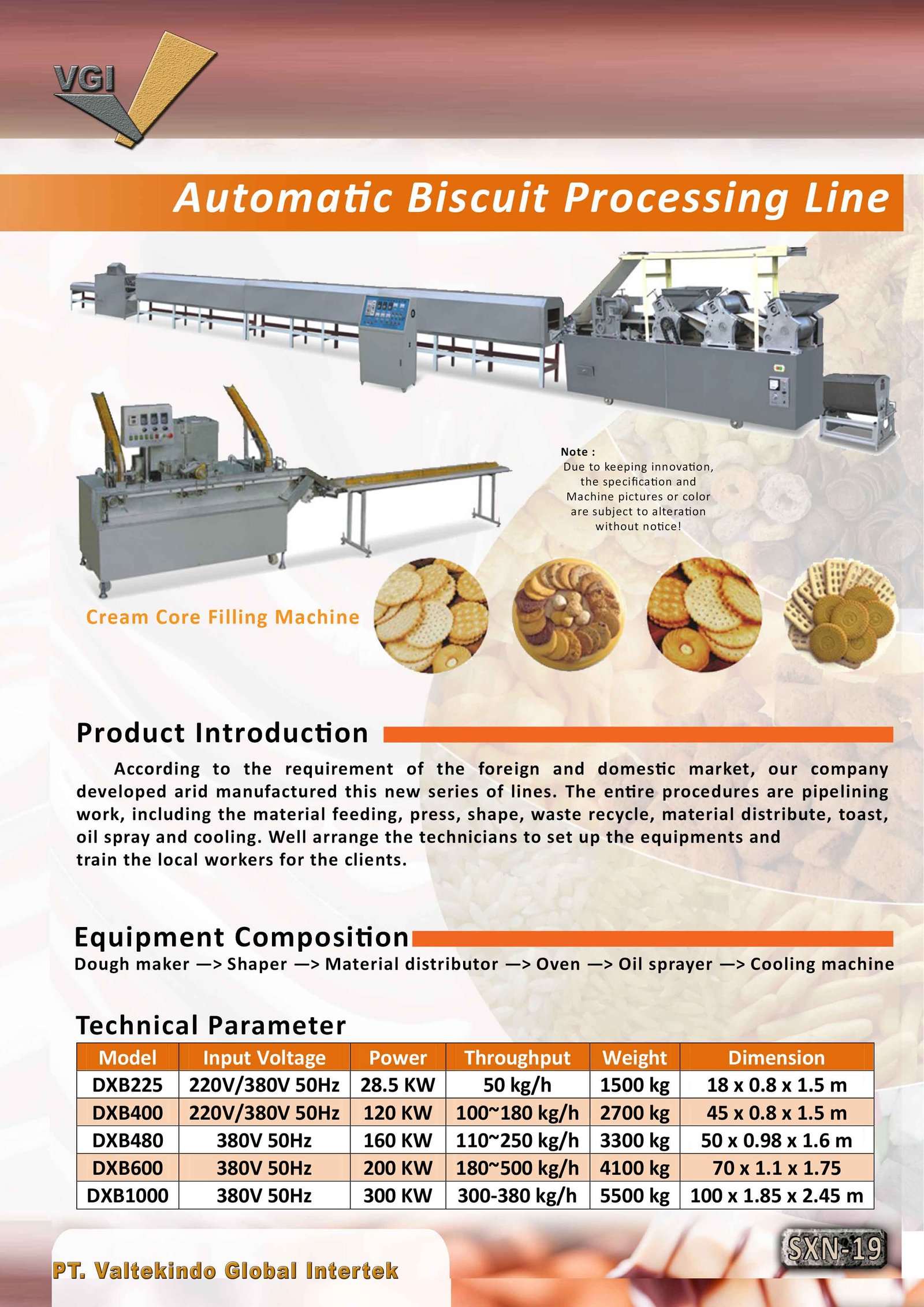

Biscuit Processing Line

Product

Introduction

According to the

requirement of the foreign and domestic market, our company developed arid

manufactured this new series of lines. The entire procedures are pipelining

work, including the material feeding, press, shape, waste recycle, material

distribute, toast, oil spray and cooling. Well arrange the technicians to set

up the equipments and

train the local

workers for the clients.

Equipment

Composition

Dough maker —>

Shaper —> Material distributor —> Oven —> Oil sprayer —> Cooling

machine

Technical

Parameter

|

Model |

Input Voltage |

Power

|

Throughput |

Weight |

Dimension |

|

DXB225 |

220V/380V 50Hz |

28.5 kW |

50 Kg/h |

1500 Kg |

18 x 0.8 x 1.5 m |

|

DXB400 |

220V/380V 50Hz |

120 kW |

100~180 Kg/h |

2700 Kg |

45 x 0.8 x 1.5 m |

|

DXB480 |

380V 50Hz |

160 kW |

110~250 Kg/h |

3300 Kg |

50 x 0.98 x 1.6 m |

|

DXB600 |

380V 50Hz |

200 kW |

180~500 Kg/h |

4100 Kg |

70 x 1.1 x 1.75 m |

|

DXB1000 |

380V 50Hz |

300 kW |

300~380 Kg/h |

5500 Kg |

100 x 1.85 x 2.45 m |