Auto Weighing and Packing Line System

MAIN

PARAMETERS:

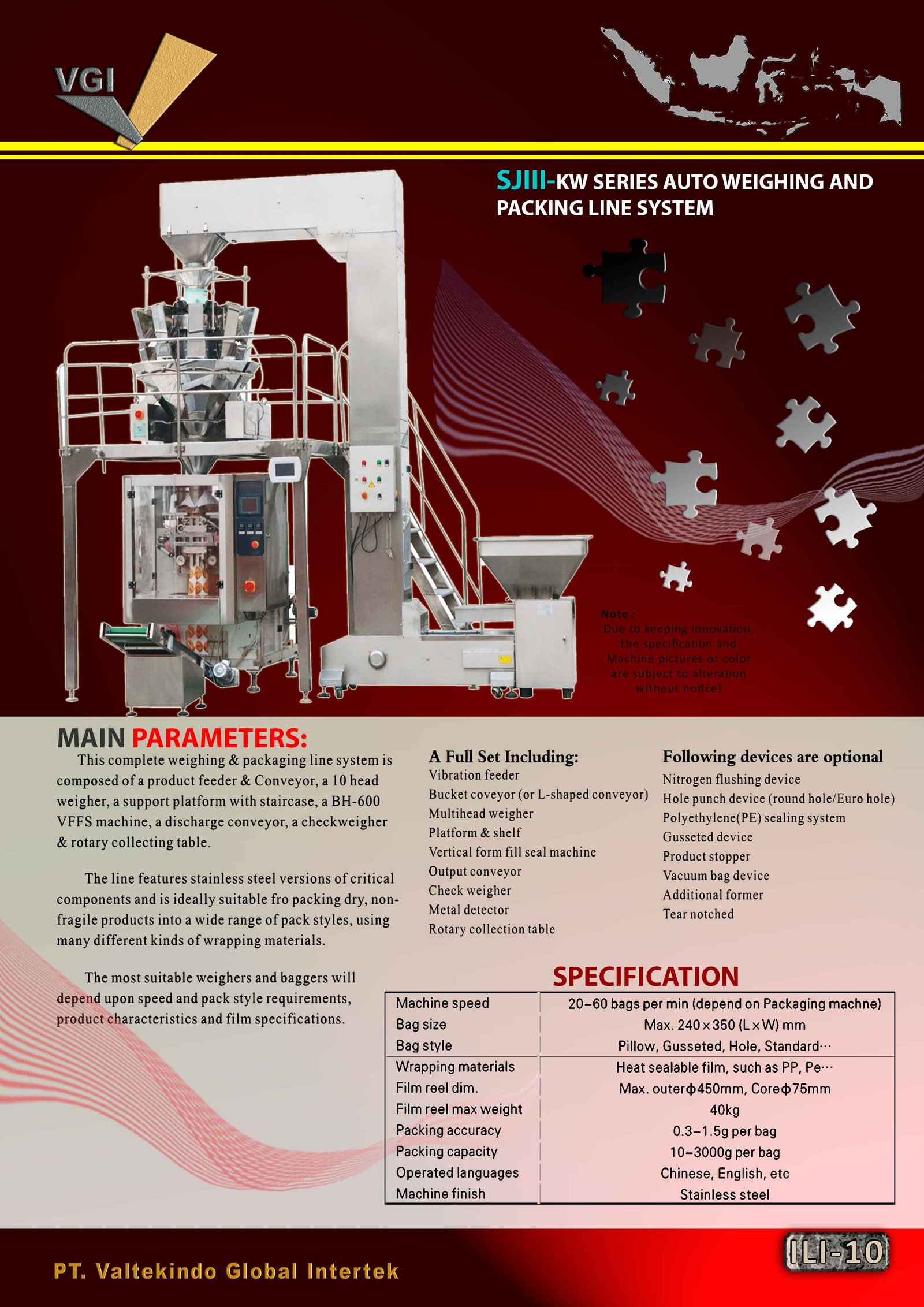

This

complete weighing & packaging line system is composed of a product feeder

& Conveyor, a 10 head weigher, a support platform with staircase, a BH-600

VFFS machine, a discharge conveyor, a check weigher & rotary collecting

table.

The line

features stainless steel versions of critical components and is ideally

suitable fro packaging dry, non-fragile productions into a wide range of pack

styles, using many different kinds of wrapping materials.

The most

suitable weigher and baggers will depend upon speed and pack style

requirements, product characteristics and film specifications.

A

Full Set Including :

Vibration

feeder

Bucket

conveyor (or L-shaped conveyor)

Multi head

weigher

Platform

form fill seal machine

Output

conveyor

Check

weigher

Metal

detector

Rotary

collection table

Following

devices are optional :

Nitrogen

flushing device

Hole punch

device (round hole/Euro hole)

Polyethlene

(PE) sealing system

Gusseted

device

Product

stopper

Vacuum bag

device

Additional

former

Tear

notched

SPECIFICATION

|

Machine

speed Bag size Bag

style |

20-60

bags per min (depend on Packaging machine) Max.240x350

(LxW) mm Pillow,

Gusseted, Hole Standard…. |

|

Wrapping

materials Films

reel dim. Film

reel max weight Packaging

accurary Packaging

Capacity Operated

languages Machine

finish |

Heat

sealable film, such as PP, Pe.. Max. other

ɸ 450mm, Core ɸ 75mm 40Kg 0.3-1.5g

per bag 10-3000g

per bag Chinese,

English, etc Stainless

steel |