Spesifikasi 1

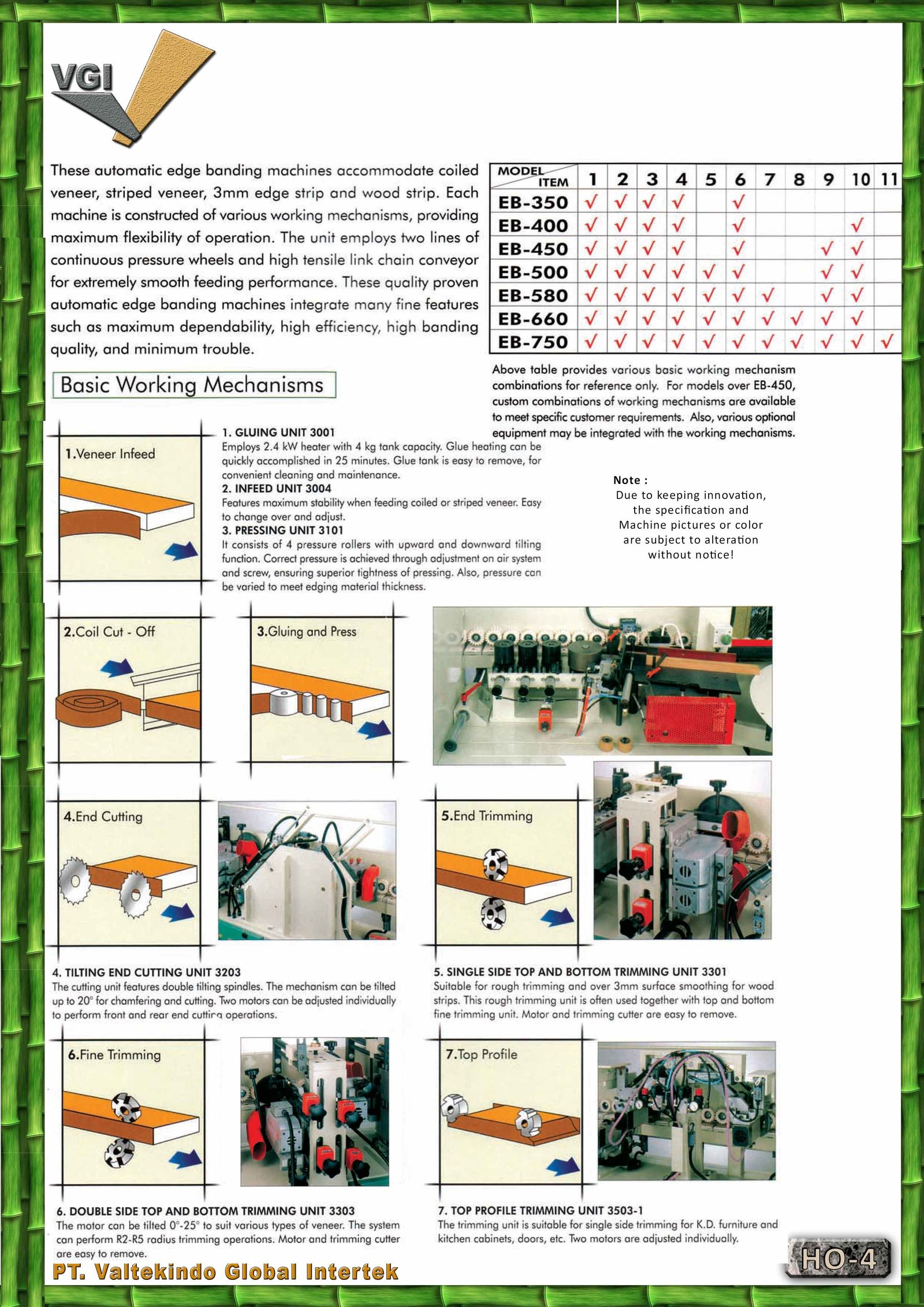

These automatic edge banding machines accommodate coiled veneer, striped veneer, 3mm edge strip and wood strip. Each machine is contracted of various working mechanism, providing maximum flexibility of operation. The unit employs two lines of continuo’s pressure wheels and high tensile link chain conveyor for extremely smooth feeding performance. These quality proven automatic edge banding machines integrate many fine features such as maximum dependability, high efficiency, high banding quality, and minimum trouble.

|

MODEL ITEM |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

|

EB-350 |

√ |

√ |

√ |

√ |

|

√ |

|

|

|

|

|

|

EB-400 |

√ |

√ |

√ |

√ |

|

√ |

|

|

|

√ |

|

|

EB-450 |

√ |

√ |

√ |

√ |

|

√ |

|

|

√ |

√ |

|

|

EB-500 |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

√ |

√ |

|

|

EB-580 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

√ |

√ |

|

|

EB-660 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

EB-750 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

Above table provides various basic working mechanism combinations for reference only. For models over EB-450, custom combinations of working mechanisms are available to meet specific customer requirements. Also, various optional equipment may be integrated with the working mechanisms.

Basic Working Mechanisms

1. GLUING UNIT 3001

Employs 2.4 kW heater with 4 kg tank capacity. Glue heating can be quickly accomplished in 25 minutes. Glue tank is easy to remove, for convenient cleaning and maintenance.

2. INFEED UNIT 3004

Features maximum stability when feeding coiled or shipped veneer. Easy to change over and adjust.

3. PRECISION UNIT 3101

It consists of 4 pressure rollers with upward and down word tilting functions. Correct pressure is achieved through adjustment on air system and screw, ensuring superior tightness of pressing. Also, pressure can be varied to meet edging materials thickness.

4. TILTING END CUTTING UNIT 3203

The cutting unit features double tilting spindles. The mechanism can be tilted up to 20o for chamfering and cutting. Two motors can be adjusted individually to perform front and rear end cutting operations.

5. SINGLE SIDE TOP AND BOTTOM TRIMMING UNIT 3301

Suitable for rough trimming and over 3mm surface smoothing for wood strips. This rough trimming unit is often used together with top and bottom fine trimming unit. Motor and trimming cuter are easy to remove.

6. DOUBLE SIDE TOP AND BOTTOM TRIMMING UNIT 3303

The motor can be tilted 0o-25o to suit various types of veneer. The system can perform R2-R5 radius trimming cuter are easy to remove.

7. TOP PROFILE TRIMMING UNIT 3503-1