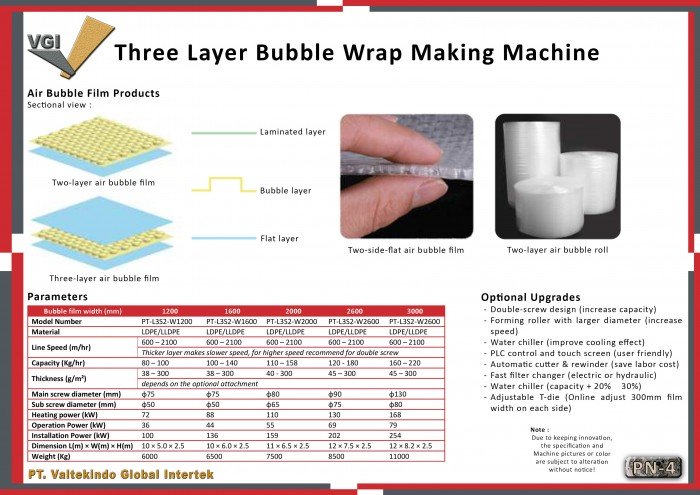

Three Layer Bubble Wrap Making Machine

Air bubble film products

Sectional view: Two-layer air bubble film, Three-layer air bubble film

Laminated layer , Bubble layer, Flat layer

Parameters

|

Bubble film width (mm) |

1200 |

1600 |

2000 |

2600 |

3000 |

|

Model Number |

PT-L3S2-W1200 |

PT-L3S2-W1600 |

PT-L3S2-W2000 |

PT-L3S2-W2600 |

PT-L3S2-W2600 |

|

Material |

LDPE/LLDPE |

LDPE/LLDPE |

LDPE/LLDPE |

LDPE/LLDPE |

LDPE/LLDPE |

|

Line Speed (m/hr) |

600 – 2100 |

600 – 2100 |

600 – 2100 |

600 – 2100 |

600 – 2100 |

|

Thicker layer makes slower speed, for higher speed recommend for double screw |

|||||

|

Capacity (Kg/hr) |

80 – 100 |

100 – 140 |

110 – 158 |

120 - 180 |

160 – 220 |

|

Thickness (g/m²) |

38 – 300 |

38 – 300 |

40 - 300 |

45 – 300 |

45 – 300 |

|

depends on the optional attachment |

|||||

|

Main screw diameter (mm) |

?75 |

?75 |

?80 |

?90 |

?130 |

|

Sub screw diameter (mm) |

?50 |

?50 |

?65 |

?75 |

?80 |

|

Heating power (kW) |

72 |

88 |

110 |

130 |

168 |

|

Operation Power (kW) |

36 |

44 |

55 |

69 |

79 |

|

Installation Power (kW) |

100 |

136 |

159 |

202 |

254 |

|

Dimension L(m) × W(m) × H(m) |

10 × 5.0 × 2.5 |

10 × 6.0 × 2.5 |

11 × 6.5 × 2.5 |

12 × 7.5 × 2.5 |

12 × 8.2 × 2.5 |

|

Weight (Kg) |

6000 |

6500 |

7500 |

8500 |

11000 |

*Recommended FMI of LDPE material is 2.0 - 2.5;We support custom solutions according to your needs

Optional Upgrades

- Double-screw design (increase capacity)

- Forming roller with larger diameter (increase speed)

- Water chiller (improve cooling effect)

- PLC control and touch screen (user friendly)

- Automatic cutter & rewinder (save labor cost)

- Fast filter changer (electric or hydraulic)

- Water chiller (capacity + 20% - 30%)

- Adjustable T-die (Online adjust 300mm film width on each side