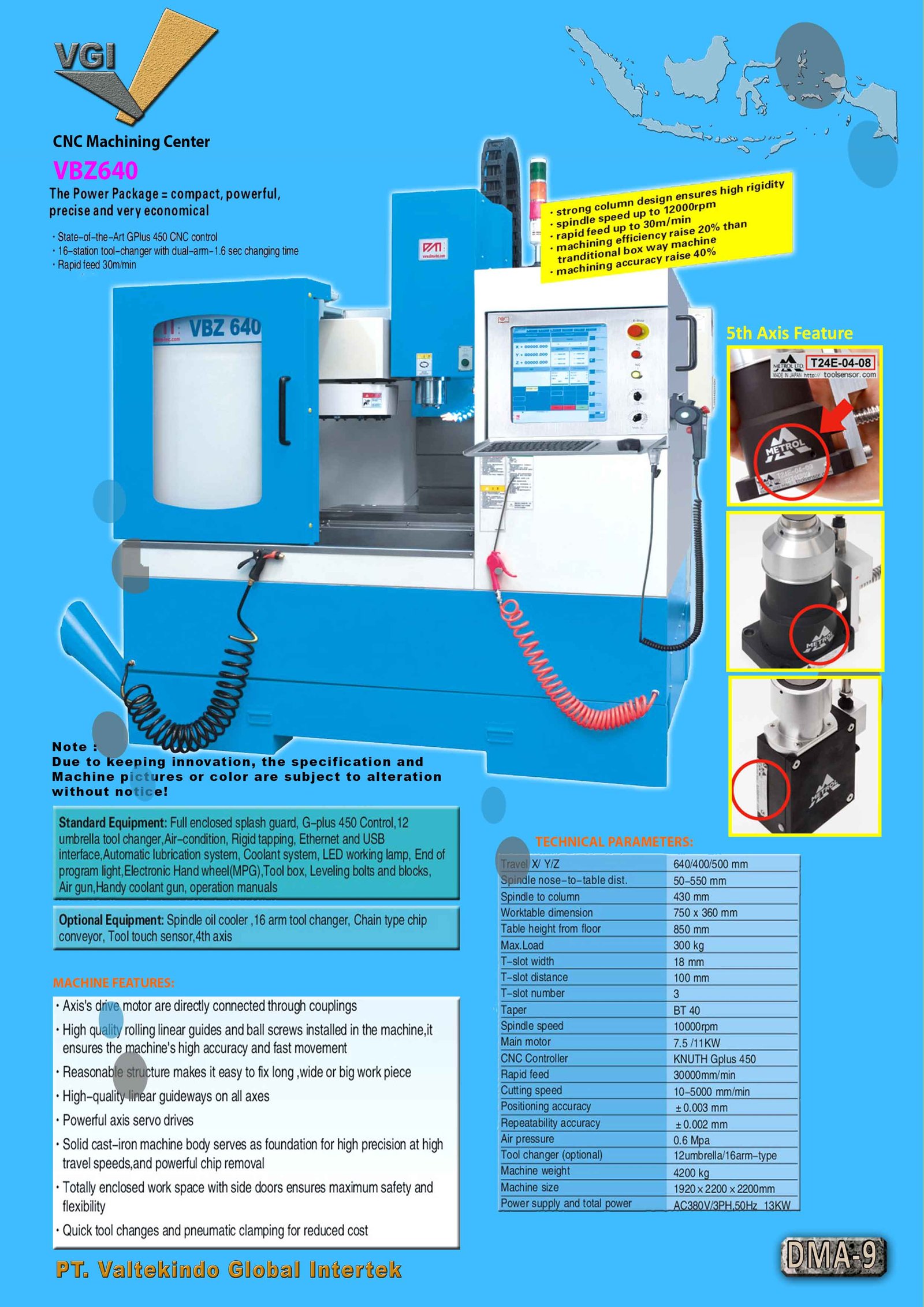

High Quality Machining Center

Standard Equipment : Full enclosed splash guard, G-plus 450 control, 12 umbrella tool changer, air-condition, rigid taping, Ethernet and USB interface, automatic lubrication system, coolant system, LED working lamp, end of program light, electronic hand wheel (MPG), tool box, leveling bolts and blocks, air gun, handy coolant gun, operation manuals.

Optional Equipment : spindle oil cooler, 16 arm tool changer, chain type chip conveyor, tool touch sensor, 4th axis

MACHINE FEATURES :

· Axis drive motor are directly connected through couplings

· High quality rolling linear guides and ball screws installed in the machine, it ensures the machine’s high accuracy and fast movement

· Reasonable structure makes it easy to fix long, wide or big work piece

· High-quality linear guide ways on all axes

· Powerful axis servo drives

· Solid cast-iron machine body serves as foundation for high precision at high travel speeds, and powerful chip removal

· Totally enclosed work space with side doors ensures maximum safety and flexibility

· Quick tool changes and pneumatic clamping for reduced cost

TECHNICAL PARAMETERS :

|

Travel X/Y/Z |

640/400/500mm |

|

Spindle nose-to-table dist. |

50-550mm |

|

Spindle to column |

430mm |

|

Worktable dimension |

750x360mm |

|

Table height from floor |

850mm |

|

Max. load |

300 kg |

|

T-slot width |

18mm |

|

T- slot distance |

100mm |

|

T- slot number |

3 |

|

Taper |

BT 40 |

|

Spindle speed |

10000rpm |

|

Main motor |

7.5/11kW |

|

CNC controller |

KNUTH G-plus 450 |

|

Rapid feed |

30000mm/min |

|

Cutting speed |

10-5000mm/min |

|

Positioning accuracy |

±0.003mm |

|

Repeat ability accuracy |

±0.002mm |

|

Air pressure |

0.6mpa |

|

Tool changer (optional) |

12umbrella/16arm-type |

|

Machine weight |

4200kg |

|

Machine size |

1920x2200x2200mm |

|

Power supply and total power |

AC380V3PH,50Hz 13KW |