CNC Wire Bending (Penekuk Pembengkok)

Product Description:

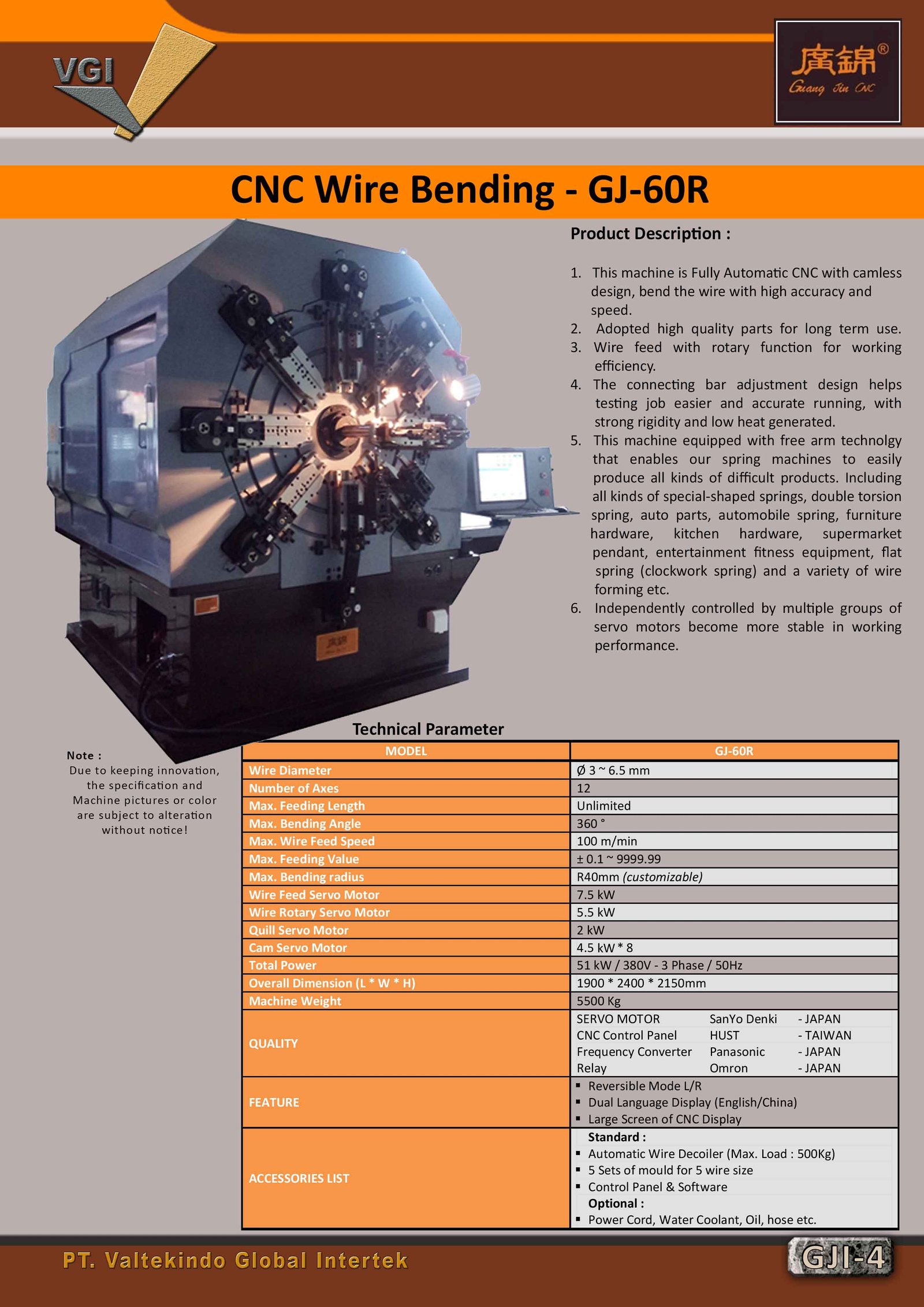

1.This machine is fully automatic CNC with camels design, bend the wire with high accuracy and speed.

2.Adopted high quality parts for long term use.

3.Wire feed with rotary function for working efficiency.

4.The connecting bar adjustment design helps testing job easier and accurate running, with strong rigidity and low heat generated.

5. This machine equipped with free arm technology that enables our spring machines to easily produce all kinds of difficult products. Including all kinds of special-shaped springs, double torsion spring, auto parts, automobile spring, furniture hardware, kitchen hardware, supermarket pendant, entertainment fitness equipment, flat spring (clockwork spring) and a variety of wire forming etc.

6.Independently controlled by multiple groups of servo motors become more stable in working performance.

|

Model |

GJ-60R |

|

Wire Diameter |

Ø3~6.5mm |

|

Number of Axes |

12 |

|

Max. Feeding Length |

Unlimited |

|

Max. Bending Angle |

360o |

|

Max. Wire Feed Speed |

100 m/min |

|

Max Feeding Value |

±0.1~9999.99 |

|

Max. Bending radius |

R40mm (customizable) |

|

Wire Feed Servo Motor |

7.5kw |

|

Wire Rotary Servo Motor |

5.5kw |

|

Quill Servo Motor |

2kw |

|

Cam Servo Motor |

4.5kw*8 |

|

Total Power |

51kw/380V-3 Phase/50Hz |

|

Overall Dimension (L*W*H) |

1900*2400*2150mm |

|

Machine Weight |

5500kg |

|

Quality |

Servo Motor Sanyo Denki – JAPAN CNC Control Panel HUST –TAIWAN Frequency Converter Panasonic –JAPAN Relay Omron –JAPAN |

|

Feature |

-Reversible Mode L/R -Dual Language Display (English/China) -Large Screen of CNC Display |

|

Accessories List |

Standard: -Automatic Wire Decoyer (Max.Load:500kg) -5sets of mould for 5 wire size -Control Panel & Software Optional: -Power Cord, Water Coolant, Oil, hose etc. |