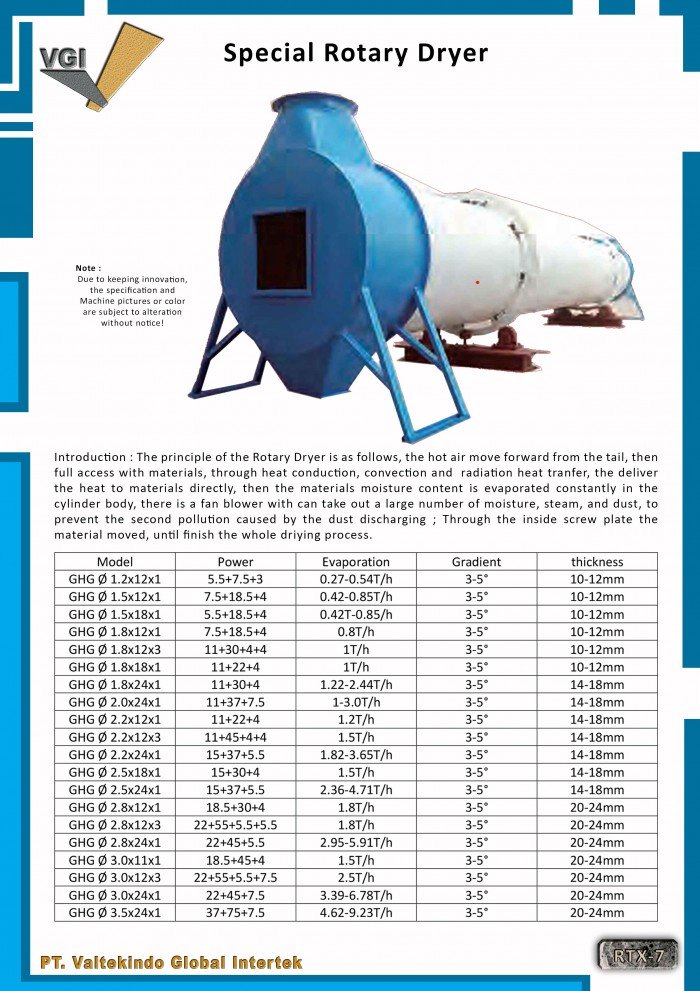

Special Rotary Dryer

Introduction : The principle of the Rotary Dryer is as follows, the hot air move forward from the tail, then full access with materials, through heat conduction, convection and radiation heat tranfer, the deliver the heat to materials directly, then the materials moisture content is evaporated constantly in the cylinder body, there is a fan blower with can take out a large number of moisture, steam, and dust, to prevent the second pollution caused by the dust discharging ; Through the inside screw plate the material moved, until finish the whole driying process.

|

Model |

Power |

Evaporation |

Gradient |

thickness |

|

GHG Ø 1.2x12x1 |

5.5+7.5+3 |

0.27-0.54T/h |

3-5° |

10-12mm |

|

GHG Ø 1.5x12x1 |

7.5+18.5+4 |

0.42-0.85T/h |

3-5° |

10-12mm |

|

GHG Ø 1.5x18x1 |

5.5+18.5+4 |

0.42T-0.85/h |

3-5° |

10-12mm |

|

GHG Ø 1.8x12x1 |

7.5+18.5+4 |

0.8T/h |

3-5° |

10-12mm |

|

GHG Ø 1.8x12x3 |

11+30+4+4 |

1T/h |

3-5° |

10-12mm |

|

GHG Ø 1.8x18x1 |

11+22+4 |

1T/h |

3-5° |

10-12mm |

|

GHG Ø 1.8x24x1 |

11+30+4 |

1.22-2.44T/h |

3-5° |

14-18mm |

|

GHG Ø 2.0x24x1 |

11+37+7.5 |

1-3.0T/h |

3-5° |

14-18mm |

|

GHG Ø 2.2x12x1 |

11+22+4 |

1.2T/h |

3-5° |

14-18mm |

|

GHG Ø 2.2x12x3 |

11+45+4+4 |

1.5T/h |

3-5° |

14-18mm |

|

GHG Ø 2.2x24x1 |

15+37+5.5 |

1.82-3.65T/h |

3-5° |

14-18mm |

|

GHG Ø 2.5x18x1 |

15+30+4 |

1.5T/h |

3-5° |

14-18mm |

|

GHG Ø 2.5x24x1 |

15+37+5.5 |

2.36-4.71T/h |

3-5° |

14-18mm |

|

GHG Ø 2.8x12x1 |

18.5+30+4 |

1.8T/h |

3-5° |

20-24mm |

|

GHG Ø 2.8x12x3 |

22+55+5.5+5.5 |

1.8T/h |

3-5° |

20-24mm |

|

GHG Ø 2.8x24x1 |

22+45+5.5 |

2.95-5.91T/h |

3-5° |

20-24mm |

|

GHG Ø 3.0x11x1 |

18.5+45+4 |

1.5T/h |

3-5° |

20-24mm |

|

GHG Ø 3.0x12x3 |

22+55+5.5+7.5 |

2.5T/h |

3-5° |

20-24mm |

|

GHG Ø 3.0x24x1 |

22+45+7.5 |

3.39-6.78T/h |

3-5° |

20-24mm |

|

GHG Ø 3.5x24x1 |

37+75+7.5 |

4.62-9.23T/h |

3-5° |

20-24mm |