Mesin Pembuat Strip Packing Obat Kapsul Capsule Tablet Medicine Packaging (Specification)

Brosur dapat anda Download pada tombol dibawah ini, atau hubungi kami untuk penjelasan lebih detail nya.

------------------

You can download the technical specifications in the brochure below, or you can contact us directly for more detail explanation.

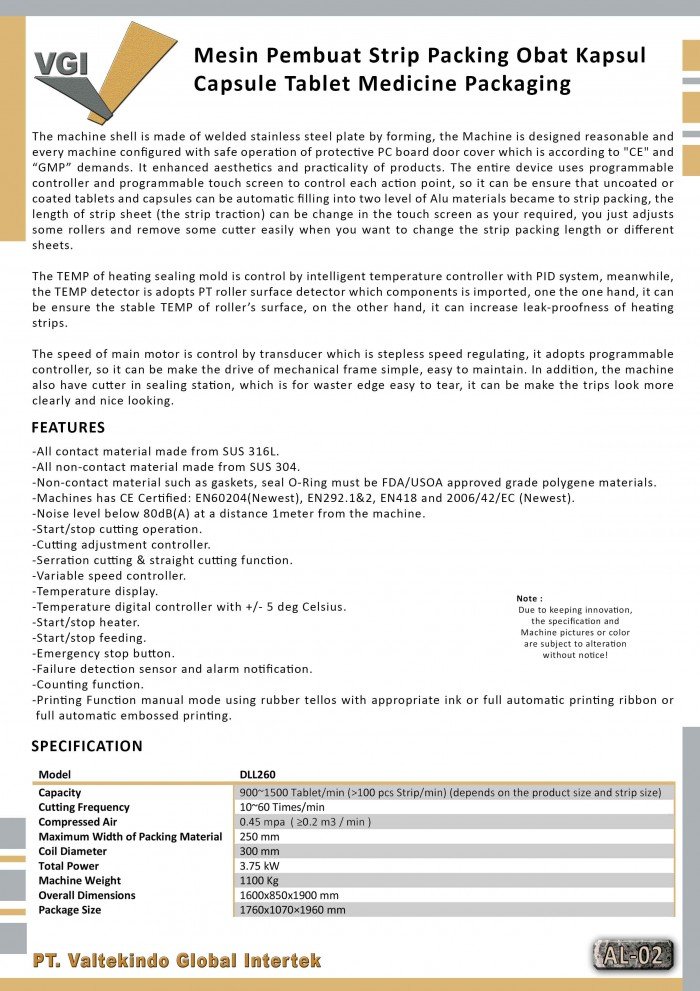

The machine shell is made of welded stainless steel plate by forming, the Machine is designed reasonable and every machine configured with safe operation of protective PC board door cover which is according to "CE" and “GMP” demands. It enhanced aesthetics and practicality of products. The entire device uses programmable controller and programmable touch screen to control each action point, so it can be ensure that uncoated or coated tablets and capsules can be automatic filling into two level of Alu materials became to strip packing, the length of strip sheet (the strip traction) can be change in the touch screen as your required, you just adjusts some rollers and remove some cutter easily when you want to change the strip packing length or different sheets.

The TEMP of heating sealing mold is control by intelligent temperature controller with PID system, meanwhile, the TEMP detector is adopts PT roller surface detector which components is imported, one the one hand, it can be ensure the stable TEMP of roller’s surface, on the other hand, it can increase leak-proofness of heating strips.

The speed of main motor is control by transducer which is stepless speed regulating, it adopts programmable controller, so it can be make the drive of mechanical frame simple, easy to maintain. In addition, the machine also have cutter in sealing station, which is for waster edge easy to tear, it can be make the trips look more clearly and nice looking.

FEATURES

- All contact material made from SUS 316L.

- All non-contact material made from SUS 304.

- Non-contact material such as gaskets, seal O-Ring must be FDA/USOA approved grade polygene materials.

- Machines has CE Certified: EN60204(Newest), EN292.1&2, EN418 and 2006/42/EC (Newest).

- Noise level below 80dB(A) at a distance 1meter from the machine.

- Start/stop cutting operation.

- Cutting adjustment controller.

- Serration cutting & straight cutting function.

- Variable speed controller.

- Temperature display.

- Temperature digital controller with +/- 5 deg Celsius.

- Start/stop heater.

- Start/stop feeding.

- Emergency stop button.

- Failure detection sensor and alarm notification.

- Counting function.

- Printing Function manual mode using rubber tellos with appropriate ink or full automatic printing ribbon or full automatic embossed printing.

|

Model |

DLL260 |

|

Capacity |

900~1500 Tablet/min (>100 pcs Strip/min) (depends on the product size and strip size) |

|

Cutting Frequency |

10~60 Times/min |

|

Compressed Air |

0.45 mpa ( ≥0.2 m3 / min ) |

|

Maximum Width of Packing Material |

250 mm |

|

Coil Diameter |

300 mm |

|

Total Power |

3.75 kW |

|

Machine Weight |

1100 Kg |

|

Overall Dimensions |

1600x850x1900 mm |

|

Package Size |

1760x1070×1960 mm |