Filling Honey

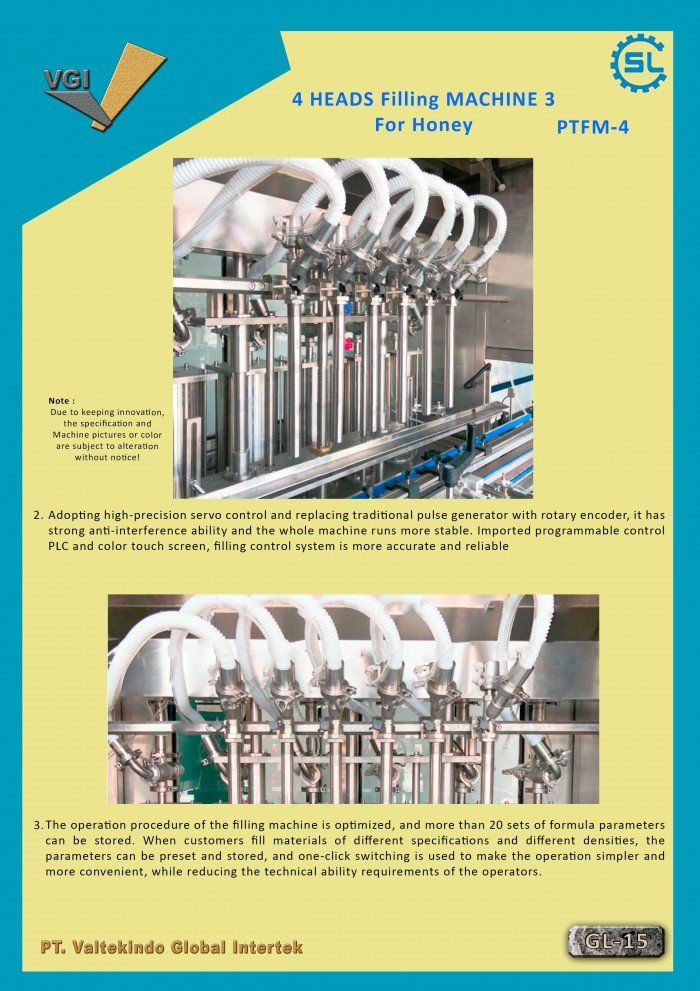

2. Adopting high-precision servo control and replacing traditional pulse generator with rotary encoder, it has strong anti-interference ability and the whole machine runs more stable. Imported programmable control PLC and color touch screen, filling control system is more accurate and reliable

3. The operation procedure of the filling machine is optimized, and more than 20 sets of formula parameters can be stored. When customers fill materials of different specifications and different densities, the parameters can be preset and stored, and one-click switching is used to make the operation simpler and more convenient, while reducing the technical ability requirements of the operators.