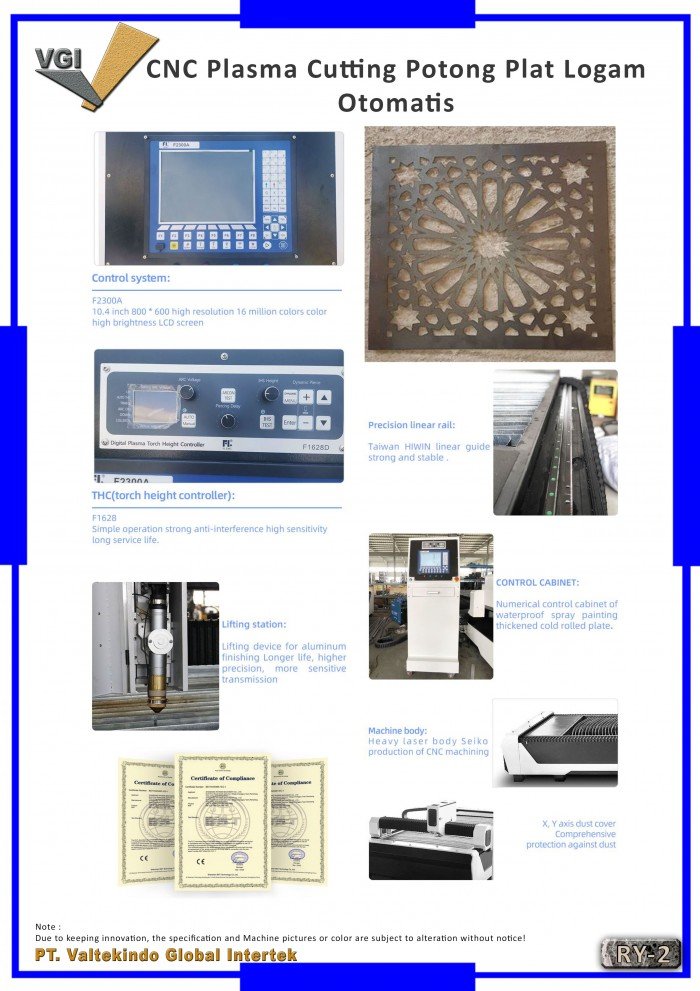

Feature CNC Plasma Cutting Potong Plat Logam Otomatis

It is used for cutting of metal sheet for making all the difficult shape, lettering also

can do various cutting metal material such as carbon steel, stainless steel, aluminum etc

Plasma cutting (plasma arc cutting) is a melting process in which a jet of ionized gas at temperatures above 20,000°C is used to melt and expel material from the cut. During the process, an electric arc is struck

between an electrode (cathode) and the workpiece (anode).

|

Model |

RM-T1325 |

RM-T1530 |

RM-T2040 |

|

Working size |

1300*2500mm |

1500*3000mm |

2000*4000mm |

|

Adjustable Height of cutting torch |

100mm |

||

|

Driving mode |

Double side driving |

||

|

Lifting station |

One set for plasma cutting torch |

||

|

Precision of rise and fall |

±0.2mm |

||

|

Precision of line position |

±0.4mm/10m |

||

|

Transmission system |

X,Y Taiwan AMT high-precision, zero clearance increased linear guide + rack Z the arc voltage control |

||

|

No-load travel speed |

15000mm/min |

||

|

Working voltage |

3~ 220/50HZ |

||

|

Control system |

Beijing START plasma cutting system |

||

|

Software support |

Starcam, FASTCAM, AutoCAD |

||

|

Instruction format |

G code |

||

|

Drive system |

Stepper motor or Panasonic Servo motor |

||

|

Plasma power |

Chinese Huayuan brand plasma powers 40A to 400A (based on request) |

||

|

Power cutting thickness |

0.3mm to 30mm |

||